Backup Water Heater Guide: Never Take a Cold Shower Again

Imagine waking up on a freezing winter morning, stepping into the shower, and being greeted by an icy blast of water because your main heater failed overnight. This scenario is a nightmare for homeowners, yet it happens far too frequently due to aging systems or unexpected mechanical failures. A backup water heater acts as a redundant system, typically configured in series or parallel, ensuring your home maintains a continuous hot water supply even if the primary unit fails or undergoes maintenance. Beyond just emergencies, these systems can supplement your daily capacity to ensure you never run out during high-demand periods.

Relying on a single appliance for a critical home function creates a significant point of vulnerability. When a standard tank fails, it often involves a complete shutdown of hot water for days while you wait for parts or a plumber. A secondary unit eliminates this downtime immediately. It transforms a household crisis into a minor inconvenience that can be addressed on your own schedule.

The concept of redundancy is standard in commercial buildings, but savvy homeowners are now adopting it for residential peace of mind. Implementing a backup strategy requires understanding the difference between boosting capacity and true emergency redundancy. This guide explores the engineering, installation strategies, and benefits of installing a secondary hot water system.

You'll Learn About

The Hidden Vulnerabilities of Single-Heater Homes

Most residential building codes require only one water heater, assuming it will suffice for the average family’s needs. However, modern hot water consumption often exceeds the recovery rate of standard 40 or 50-gallon tanks. If you have a large soaking tub or multiple showers running simultaneously, a single unit struggles to keep up. This strain forces the unit to run constantly, accelerating wear and tear on burners and heating elements.

Sediment buildup is another silent killer of solitary systems. Over time, minerals settle at the bottom of the tank, insulating the water from the heat source and causing the metal to overheat and crack. When this inevitable failure occurs, you are left without options. A backup system provides a safety net against these predictable mechanical lifecycles.

Furthermore, supply chain issues can delay replacements for specific high-efficiency models. Having a secondary unit installed means you are not at the mercy of local inventory availability during a breakdown. You can take the time to source the correct replacement fixture or heater without enduring cold showers. This strategic patience saves money by preventing panic buying.

Types of Backup Water Heater Configurations

Not all backup systems look or function the same way. The market offers various solutions ranging from compact electric units to full-sized gas hybrids. Choosing the right hardware depends on your available space, fuel source, and specific goals for redundancy. You must decide if you want a system that sits idle until needed or one that actively assists your primary unit.

Tankless Electric Point-of-Use Units

A popular and space-saving option is the electric tankless water heater. These compact units can be mounted on a wall near specific fixtures or inline with the main plumbing. Because they do not store water, they eliminate standby heat loss completely. In a backup scenario, a tankless unit can be bypassed into the main line to provide emergency hot water.

These units are excellent for redundancy because they require minimal maintenance while inactive. They sit dormant until flow is detected or valves are switched. However, they do require significant electrical amperage. You must ensure your home’s electrical panel can handle the sudden load of a high-powered electric heater.

Secondary Tank Systems

For homes with high volume needs, a second storage tank is often the most practical solution. This involves installing two identical or similar tank heaters next to each other. This setup provides the highest level of redundancy because either unit can carry the entire household load independently. It essentially doubles your available hot water inventory.

The downside to this approach is the physical footprint required in your utility room or garage. You also have to manage the maintenance of two separate large appliances. However, for large families, the benefit of never running out of hot water outweighs the spatial costs.

Hybrid Heat Pump Integration

A modern approach involves pairing a standard gas tank with a hybrid electric heat pump water heater. The heat pump acts as the primary efficient source, while the gas unit serves as a high-recovery backup. This hybrid setup optimizes energy bills while providing a powerful safety net. It combines the best of efficiency and raw heating power.

Strategic Installation: Series vs. Parallel

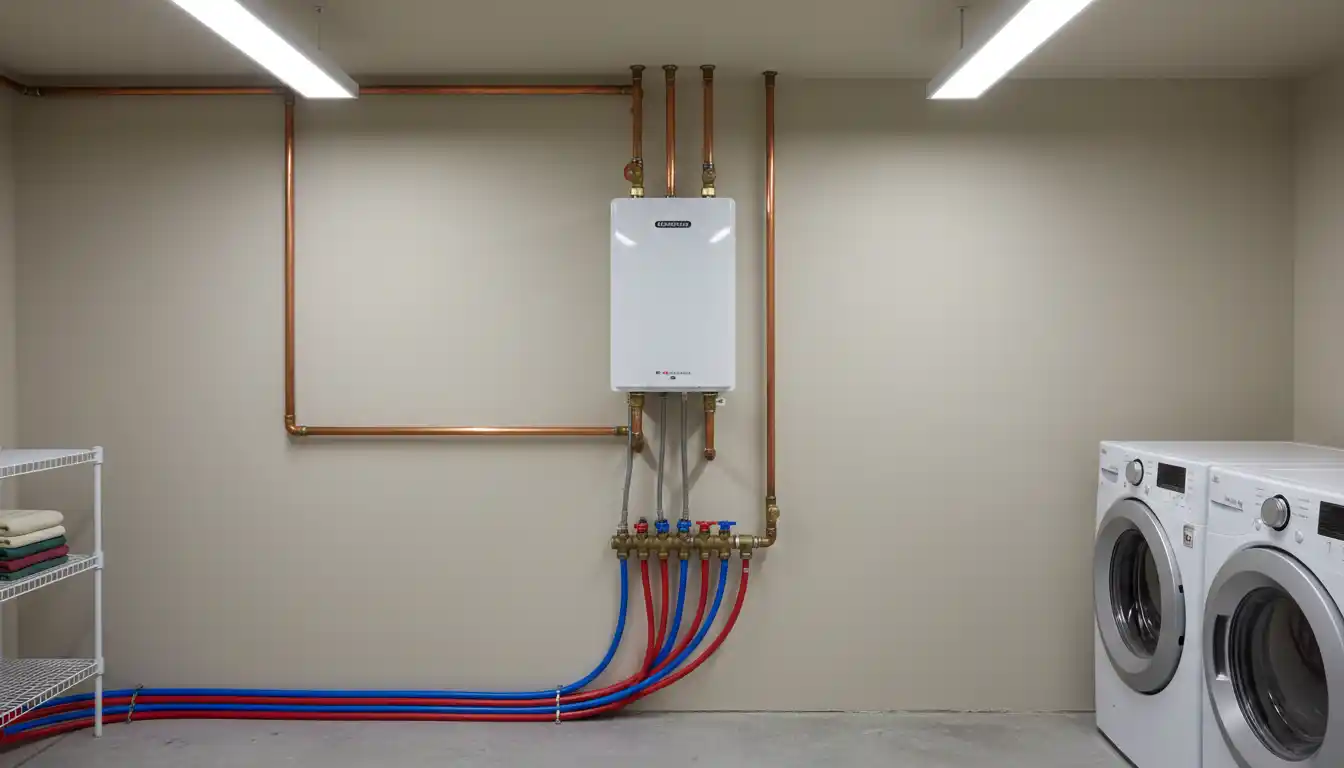

The physical plumbing connection of your backup water heater is just as important as the unit itself. The way you pipe the two units determines whether they work together or as separate entities. Professional plumbers typically utilize one of two distinct configurations: series or parallel.

The Series Configuration

In a series setup, cold water enters the first heater (the pre-heater), and the warmed water flows into the inlet of the second heater. The second unit then polishes the temperature before sending it to your taps. This is highly effective for increasing effective capacity. If the first unit fails, the second unit simply heats cold water from scratch.

This method is excellent for maximizing the output of a tankless backup feeding a storage tank. The tankless unit raises the water temperature, meaning the tank uses less energy to maintain the target heat. It reduces thermal shock to the primary tank, potentially extending its lifespan significantly.

The Parallel Configuration

Parallel piping splits the incoming cold water line evenly between two heaters. The hot water outlets then rejoin into a single supply line for the house. This method allows both units to share the workload equally. If designed correctly with isolation valves, you can shut one unit off completely for repairs while the other continues to operate.

Balancing the flow is the main challenge in parallel systems. If the piping is not perfectly symmetrical, water will follow the path of least resistance, draining one tank faster than the other. This results in uneven wear and lukewarm water mixing with hot water. Proper engineering is critical here.

The Essential Bypass Valve Setup

Regardless of the configuration, a 3-valve bypass kit is mandatory for any backup system. This arrangement allows you to isolate a specific heater from the plumbing loop without shutting off water to the entire house. Without a bypass, a leak in your backup unit could render your primary unit useless as well.

The bypass allows you to perform maintenance, such as flushing sediment, on one unit while the other runs. This capability is the core definition of a true backup system. It transforms your plumbing from a static utility into a flexible, manageable asset.

Energy Efficiency and Standby Losses

A common misconception is that running two water heaters automatically doubles your energy bill. While there is an increase, it is rarely double, especially if the system is insulated correctly. The primary cost driver in a backup system is “standby loss”—the heat that escapes through the walls of the tank while it sits idle.

Modern tanks with high R-value foam insulation minimize this loss significantly. Furthermore, if you use a tankless unit as your backup, the standby cost is effectively zero. The tankless unit consumes no energy until it is called upon to heat water. This makes on-demand units the most financially sound choice for pure emergency backup.

For series systems, the “pre-heating” effect can actually increase overall efficiency. By feeding pre-warmed water into the main tank, the primary burner fires less frequently. This reduces the thermal stress cycles on the tank’s metal glass lining.

| Feature | Series Configuration | Parallel Configuration | Tankless Backup |

|---|---|---|---|

| Primary Function | Capacity Boosting & Pre-heating | Load Sharing & Volume | Emergency Redundancy |

| Standby Energy Loss | Moderate (Two active tanks) | Moderate (Two active tanks) | Zero (On-demand only) |

| Failure Mode | One unit can bypass the other | One unit runs solo instantly | Manual switch required |

| Installation Cost | Medium | High (Complex piping) | Medium (Requires electric upgrade) |

| Maintenance Needs | Routine flush for both | Routine flush for both | Yearly descaling |

Addressing Legionella and Stagnation Risks

One technical aspect that few homeowners consider is the risk of water stagnation in a backup unit. If a backup tank sits full of water but turned off for months, it becomes a breeding ground for Legionella bacteria. This bacteria thrives in lukewarm water between 77°F and 108°F. You cannot simply leave a tank full of cold water sitting stagnant for emergencies.

To prevent this, a backup tank must either be kept hot (above 140°F) or be drained completely when not in use. Keeping it hot incurs energy costs, while draining it increases the setup time during an emergency. A tankless backup solves this issue entirely, as it holds no significant volume of water.

If you choose a tank-based backup, consider installing a recirculation pump. This pump can cycle water between the two units periodically. This ensures the water in the backup tank remains fresh, chlorinated, and hot enough to kill bacteria.

Integration with Smart Home Technology

Modern backup heaters can integrate seamlessly with home automation systems. Smart leak detectors are a crucial addition to any water heater setup. If the primary unit leaks, the smart valve can automatically shut off the water supply and send an alert to your phone. Just as you might use a robot to clean delicate oriental rugs automatically, smart valves protect your home’s infrastructure without your intervention.

Some advanced water heaters also feature Wi-Fi connectivity. This allows you to remotely turn on your backup unit if you suspect the primary is failing. You can monitor temperature trends and energy usage from an app. This data helps you predict failure before it results in a cold shower.

Smart integration also allows for “vacation mode” management. You can shut down the primary unit remotely and leave the backup on a low setting. This saves energy while ensuring the pipes don’t freeze during winter absences.

Installation Considerations and Requirements

Adding a second water heater is not a simple plug-and-play project. It requires evaluating your home’s infrastructure capacity. For gas units, you must ensure your gas line is sized correctly to supply both heaters simultaneously. An undersized gas line can cause dangerous incomplete combustion and carbon monoxide buildup.

Electrical requirements are equally stringent. An electric backup water heater often requires a dedicated 30-amp or larger 240-volt circuit. You may need to upgrade your main breaker panel to accommodate this new load. Do not attempt to share circuits with other high-power appliances like dryers or ovens.

Venting is the final major constraint for gas units. Two heaters require twice the venting capacity. You may need to install a larger chimney liner or switch to power-vented models that use PVC piping. Improper venting is a lethal safety hazard that must be assessed by a licensed professional.

Maintenance for Redundant Systems

Having two water heaters means you have two appliances to maintain. Neglecting the backup unit is a common mistake. If you don’t flush the backup unit regularly, scale will build up just as it does in the main unit. This is particularly true if the backup is used in a series configuration.

Ideally, you should flush both tanks annually to remove sediment. Check the anode rods in both units every two to three years. The anode rod protects the tank from corrosion; once it depletes, the tank will rot. A functional backup with a rusted tank is useless.

During bathroom renovations, such as when you replace the rubber seal around shower glass to prevent leaks, take the opportunity to inspect your water heater area. Look for signs of moisture or corrosion on the backup unit’s connections. Preventative visual inspections can save you thousands in water damage repairs.

Troubleshooting Common Redundancy Issues

Even with a robust backup system, issues can arise. A common problem in series setups is a pressure drop. Pushing water through two tanks creates more resistance than one. If you notice reduced water pressure at the showerhead, you may need to install a pressure booster pump or check for sediment clogs in the connecting pipes.

Another issue is “thermal stacking” in series systems. This occurs when the backup unit heats water that is already hot from the first unit, potentially triggering the Temperature and Pressure (T&P) relief valve. Installing an expansion tank is critical to absorb this excess pressure. Ensure both units have their own functioning expansion tanks.

Finally, ensure that your check valves are functioning. A failed check valve can allow hot water to migrate backward into the cold water supply. This results in warm water coming out of your cold tap, which is both annoying and a waste of energy.

Conclusion

Investing in a backup water heater is an investment in the comfort and resilience of your home. It eliminates the panic associated with sudden appliance failures and ensures your household runs smoothly regardless of mechanical issues. Whether you choose a tankless booster, a parallel tank system, or a hybrid setup, the key is proper configuration and isolation valving.

By understanding the thermodynamics of series versus parallel piping and addressing safety concerns like Legionella, you can build a bulletproof hot water system. Do not wait for your current tank to burst before considering a redundancy plan. Assess your space, budget, and energy sources today to determine the best backup strategy for your family.