Ariens SS522E Carburetor Woes? Your Ultimate Repair Guide

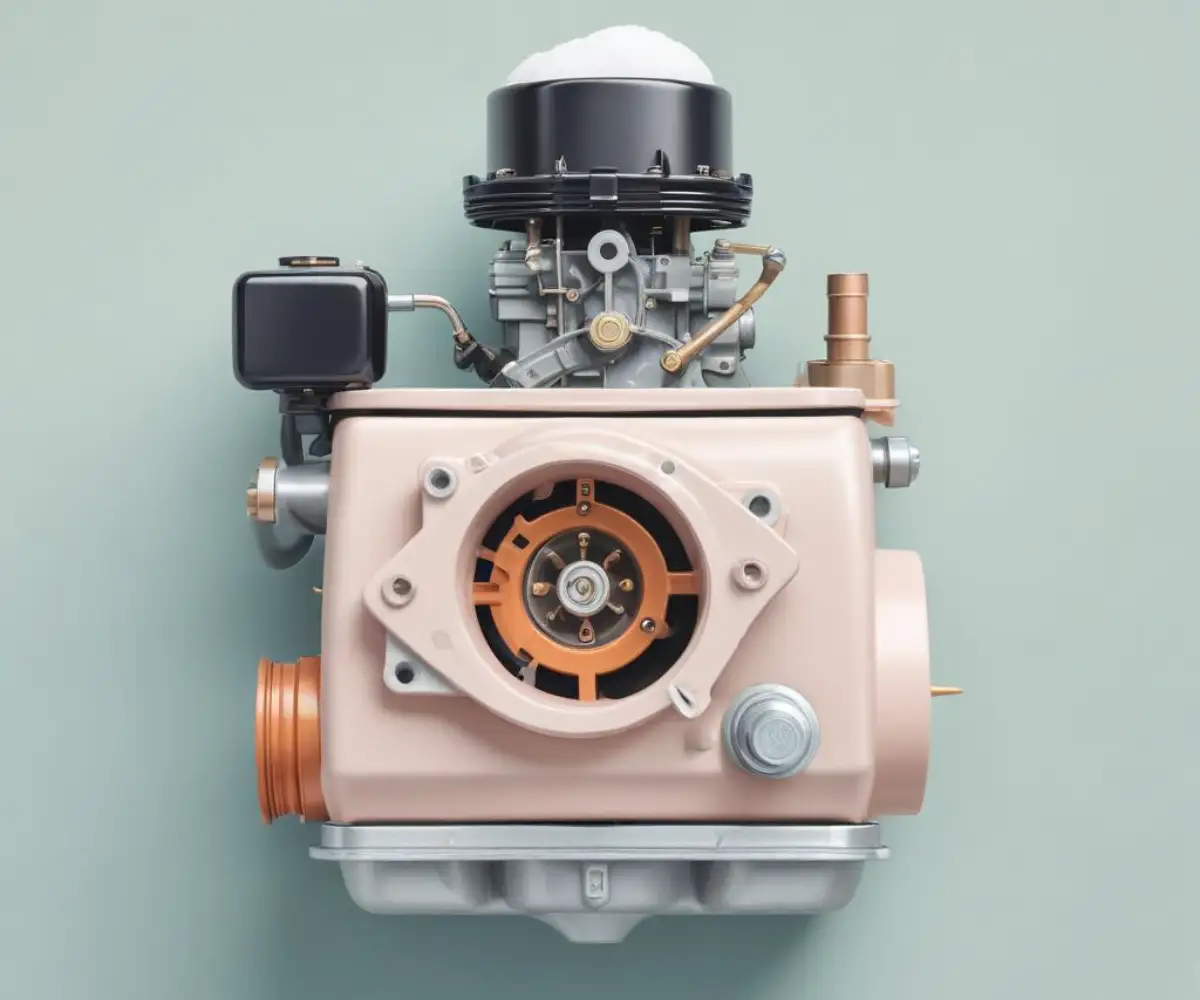

The first heavy snow of the season is blanketing your driveway, and your trusty Ariens SS522E snow blower sits ready. You pull the cord, but instead of the familiar roar, you get nothing but silence or a weak sputter. In this critical moment, the most likely culprit is a faulty or clogged Ariens SS522E carburetor, a small component responsible for a very big job.

A malfunctioning carburetor can turn a powerful snow-clearing machine into a frustratingly large paperweight. Understanding why it fails and how to fix it is essential for any snow blower owner. This guide provides a comprehensive roadmap to diagnosing, cleaning, and replacing this vital part, ensuring you’re always prepared for winter’s worst.

You'll Learn About

Decoding the Distress Call: Why Carburetors Fail

The carburetor’s primary role is to mix air and fuel in the perfect ratio for combustion. When this process is disrupted, the engine can’t run properly. The most common cause of failure, especially in seasonal equipment like snow blowers, is old fuel left in the tank.

Modern gasoline, particularly fuel containing ethanol, is the main antagonist. Ethanol attracts moisture from the air, which can lead to corrosion inside the carburetor’s delicate metal passages. Over time, ingredients in the fuel evaporate, leaving behind a thick, varnish-like substance that clogs the tiny jets and openings, effectively starving the engine of the fuel it needs to run.

The Impact of Ethanol on Small Engines

While modern cars are designed to handle ethanol-blended fuels, the small engines in equipment like the Ariens SS522E are far more susceptible to its damaging effects. The water drawn in by ethanol can cause rust and corrosion in the fuel tank and carburetor bowl. Furthermore, ethanol can degrade rubber and plastic components in the fuel system, leading to leaks and blockages from deteriorated fuel lines.

This corrosive mixture and the resulting debris are what lead to the classic symptoms of carburetor failure. Recognizing these signs early is the first step toward a successful repair and preventing a no-start situation on a snowy morning. This is a critical maintenance point that many owners overlook until it’s too late.

Pinpointing the Problem: A Diagnostic Checklist

Before you start disassembling your snow blower, it’s crucial to confirm that the carburetor is indeed the problem. A few simple checks can save you time and effort. Other issues, like a fouled spark plug or a clogged fuel filter, can mimic carburetor problems.

Use the following table to help diagnose the issue. Pay close attention to how the engine behaves when you try to start it and when it’s running, as these are key indicators of where the problem lies. Proper diagnosis ensures you’re fixing the right part.

| Symptom | Likely Carburetor-Related Cause | Other Potential Causes |

|---|---|---|

| Engine will not start at all. | Completely clogged main jet or fuel inlet. No fuel is reaching the combustion chamber. | Fouled spark plug, no fuel in tank, faulty ignition coil, sheared flywheel key. |

| Engine starts but stalls after a few seconds. | Clogged pilot jet or idle circuit. The engine gets enough fuel to start (especially with choke) but can’t sustain a slow run. | Clogged fuel cap vent, dirty fuel filter. |

| Engine runs rough, surges, or hunts (revs up and down). | Partially clogged main jet or emulsion tube. Inconsistent fuel delivery causes the engine speed to fluctuate. | Water in the fuel, air leak in the intake manifold. |

| Engine only runs with the choke on. | Clogged main jet. The choke restricts air, creating a richer fuel-to-air mixture that compensates for the fuel blockage. | Intake gasket leak. |

| Black smoke from the exhaust. | Stuck float or dirty needle valve. Too much fuel is entering the carburetor, creating a rich condition. | Incorrect choke operation. |

| Fuel leaking from the carburetor. | Stuck float, faulty needle and seat, or deteriorated bowl gasket. The carburetor bowl is overfilling and leaking fuel. | Cracked fuel line. |

The Ultimate Fix: Cleaning vs. Replacing Your Ariens Carburetor

Once you’ve confirmed a carburetor issue, you have two choices: clean the existing one or replace it entirely. For minor issues caused by recent fuel deposits, a thorough cleaning can be very effective. However, if the carburetor is heavily corroded or if you prefer a quicker, more guaranteed solution, replacement is the better option.

Carburetor replacement kits are widely available and often inexpensive. They usually include the new carburetor, gaskets, and sometimes even a new fuel line and spark plug, providing a comprehensive fuel system refresh. For many, the time saved and the assurance of a brand-new part make this the preferred route.

How to Thoroughly Clean Your Ariens SS522E Carburetor

If you opt for cleaning, meticulous attention to detail is key. A simple spray of carburetor cleaner is often not enough to dislodge the stubborn varnish and debris hidden deep within the internal passages. A full disassembly is required for a proper job.

Step 1: Removal. First, shut off the fuel valve. Carefully disconnect the fuel line, throttle linkage, and choke linkage. Be sure to note how the linkages connect to make reassembly easier. Remove the two nuts or bolts that secure the carburetor to the engine block and gently take it off, being careful not to tear the old gasket.

Step 2: Disassembly. On a clean workbench, remove the bolt at the bottom of the carburetor bowl to release the bowl itself. This bolt often doubles as the main jet; inspect the tiny holes in it for blockages. Carefully remove the float by pulling out the hinge pin. As the float comes out, the needle valve attached to it will also come free.

Step 3: Cleaning the Components. Use a quality carburetor cleaner to spray all metal parts and passages. Pay special attention to the main jet, the pilot jet (often recessed in a tube in the center of the carb), and the emulsion tube. Use a very thin wire, like a single strand from a wire brush, or a torch tip cleaner to gently poke through any blockages in the jets. Never use anything that could enlarge the jet holes, as this will permanently alter the fuel mixture.

Step 4: Rinsing and Reassembly. After cleaning, use compressed air to blow out all the passages and ensure they are clear. Reassemble the carburetor in the reverse order of disassembly. Ensure the float is set at the correct height (parallel to the carburetor body when inverted) and that the needle valve moves freely. Use a new bowl gasket and mounting gaskets to prevent air leaks.

When to Replace: Choosing the Right Carburetor Kit

Deciding to replace the carburetor is often the most efficient path. If you notice significant corrosion or pitting on the inside of the carburetor body during disassembly, cleaning is unlikely to be a long-term solution. Similarly, if you don’t have the time or the specialized tools for a deep clean, a new carburetor is a smart investment.

When buying a replacement, ensure it matches your snow blower’s engine model, which is typically a Tecumseh engine. Aftermarket carburetors are readily available and can be a cost-effective alternative to OEM parts. A fresh start with a new carburetor eliminates guesswork and gets your machine running reliably again. Proper winter preparation is a key part of home maintenance, and it’s just as important as tackling other demanding projects, whether that’s using the right technique for cutting asphalt or simply keeping your tools organized.

Proactive Maintenance: Preventing Future Carburetor Failures

The best repair is the one you never have to make. Preventing carburetor problems is straightforward and revolves around proper fuel management and storage. Following these steps can save you from future headaches and ensure your Ariens SS522E starts reliably every winter.

Use Fresh, Stabilized Fuel. Never use fuel that is more than 30 days old unless it has been treated with a fuel stabilizer. At the end of the snow season, add stabilizer to the remaining fuel and run the engine for about 10 minutes. This allows the treated fuel to circulate through the entire system, including the carburetor, protecting it during storage.

Run the Carburetor Dry. An even better method for long-term storage is to run the engine until it stops from lack of fuel. After adding stabilizer to the tank and running it for a few minutes, turn off the fuel valve and let the engine consume all the fuel left in the carburetor bowl and fuel line. A dry carburetor cannot develop clogs or corrosion.

Beyond the Carburetor: Other Potential Starting Issues

If you’ve cleaned or replaced your carburetor and the engine still won’t run correctly, the problem may lie elsewhere. Simple components are often the cause of frustrating starting issues.

Check the Spark Plug. A fouled, oily, or damaged spark plug cannot produce the strong spark needed for ignition. Remove the spark plug and inspect it. If it’s black and sooty or the electrode is worn, replace it. Making sure your workspace is clear is essential for any task; even something as simple as dealing with those old fixtures you might despise like clunky bifold doors can improve your efficiency.

Inspect the Fuel Filter and Lines. The small inline fuel filter can become clogged with debris over time, restricting fuel flow. Likewise, old fuel lines can become brittle, cracked, or internally collapsed. Replacing these inexpensive parts is good preventative maintenance. The change in seasons is a reminder to prepare; as the mornings get darker and you find you have difficulty waking up without the sun, it’s a clear signal that winter maintenance tasks are due.

By systematically addressing the fuel system, starting with the most common offender—the carburetor—you can restore your Ariens SS522E to its reliable, snow-clearing glory. A little bit of maintenance goes a long way in ensuring you’re ready to face whatever winter throws your way.