American Air Purger [Installation, Problems, Fixes]

An air purger is a device used in hydronic heating systems to remove air from the system. The presence of air in a hydronic system can cause problems such as reduced heat transfer efficiency, noisy operation, and damage to system components.

By regularly purging the air from the system, an air purger helps to ensure that the system is operating at its best and prolongs the life of the equipment. American air purgers are a popular choice for use in hydronic heating systems due to their reliable performance and durability.

In this article, we will take a closer look at how air purgers work, the different types available, and the steps for installing and maintaining an air purger in your system.

You'll Learn About

American Air Purger

The expansion tank is an important part of the system, as it helps to accommodate the expansion of water as it heats up and prevents excess pressure from building up in the system.

Pre-charged expansion tanks come with a set amount of air pressure already in them, and the pressure should not change unless there is a leak in the tank or the tank is drained. If you drained the expansion tank to reduce the pressure in the system, you may have lost some of the air pressure in the tank.

It is generally recommended to recharge the expansion tank to the correct pressure before reopening the system.

To recharge the expansion tank, you will need to locate the air valve on the tank. It may be a Schrader valve (similar to a tire valve) or a threaded valve with a cap. You will need a tire gauge or a pressure gauge to measure the pressure in the tank and a compressor or hand pump to add air to the tank.

It is important to follow the manufacturer’s recommendations for the correct pressure for your specific expansion tank.

If you are unsure about how to recharge the expansion tank or if you think there may be a leak in the tank, it is best to consult with a qualified heating professional. They can help you properly diagnose the issue and recommend the appropriate course of action.

How Air Purgers Work

Air can get trapped in a hydronic heating system in various ways, such as during installation, when the system is turned off and drained, or when the system is being repaired. The trapped air can cause issues in the system by blocking water flow and reducing heat transfer efficiency.

An air purger works by using a combination of mechanical and automatic controls to remove the trapped air from the system. It is typically installed in a strategic location in the system, such as near the expansion tank or at the highest point in the system.

The air purger has a float or diaphragm inside that is sensitive to changes in air pressure. When the float or diaphragm senses an increase in air pressure, it activates a valve or bleeder screw to release the air from the system.

The released air is then vented to the atmosphere or collected in a separate container.

By regularly purging the air from the system, an air purger helps to maintain proper system function by ensuring that the system is operating at its best and prolonging the life of the equipment. It also helps to improve the overall efficiency and comfort of the heating system by eliminating noise and reducing the risk of damage to system components.

Types of Air Purgers

There are two main types of air purgers: automatic air purgers and manual air purgers.

Automatic air purgers use a float or diaphragm to activate the purging process automatically as needed. They are typically more expensive than manual air purgers, but they require minimal maintenance and can operate continuously without the need for manual intervention. Automatic air purgers are well-suited for large or complex systems that require frequent purging or for systems that are difficult to access for manual purging.

Manual air purgers, on the other hand, require the operator to manually open and close a valve or bleeder screw to release the air from the system. They are generally less expensive than automatic air purgers and are well-suited for small or simple systems that do not require frequent purging. However, they do require more frequent maintenance and intervention to ensure that the air is being properly purged from the system.

The choice between automatic and manual air purgers ultimately depends on the specific needs of the system and the preferences of the homeowner or building owner. Both types have their own benefits and drawbacks, and it is important to carefully consider the pros and cons of each type before making a decision.

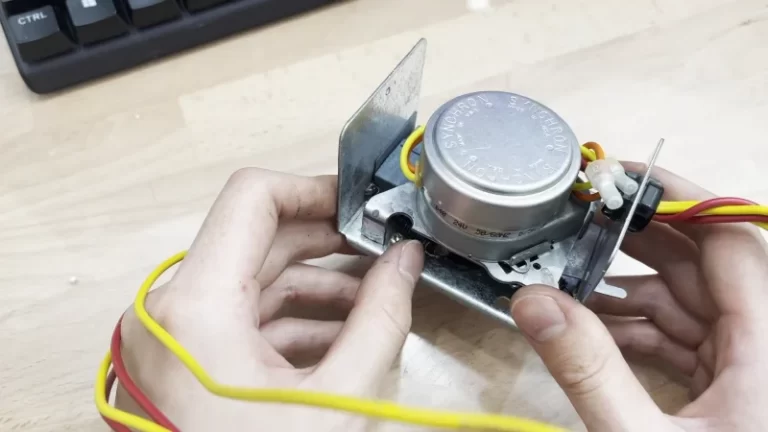

Installation and Maintenance of Air Purgers

Installing an air purger in a hydronic heating system involves the following steps:

- Determine the best location for the air purger based on the layout of the system and the manufacturer’s recommendations. It is typically installed in a strategic location in the system, such as near the expansion tank or at the highest point in the system.

- Shut off the power to the system and close the isolation valves to isolate the section of the system where the air purger will be installed.

- Install the air purger according to the manufacturer’s instructions, using the appropriate fittings and connections.

- Open the isolation valves and refill the system with water, following the manufacturer’s instructions for filling and purging the system.

- Test the air purger to ensure that it is functioning properly and releasing air as needed.

To maintain the air purger and ensure that it is operating at its best, it is important to perform the following tasks on a regular basis:

- Check the air purger for any visible signs of damage or wear and tear.

- Follow the manufacturer’s recommendations for cleaning and lubricating the air purger.

- Test the air purger regularly to ensure that it is functioning properly and releasing air as needed.

- Replace the air purger if it is damaged or not functioning properly.

If you encounter any issues with your air purger, there are a few troubleshooting tips that you can try:

- Check the air purger for visible signs of damage or wear and tear.

- Make sure that the air purger is properly installed and connected to the system.

- Check the system for any leaks or other issues that may be preventing the air purger from functioning properly.

- Consult the manufacturer’s instructions or a qualified heating professional for additional troubleshooting guidance.

Tips for Using and Maintaining an Air Purger

Here are a few additional tips for using and maintaining an air purger in a hydronic heating system:

- Make sure to follow the manufacturer’s instructions for installing and using the air purger. Different models may have different requirements for installation and operation.

- Regularly check the air purger for any visible signs of damage or wear and tear, such as cracks, leaks, or corrosion. If you notice any issues, it is important to address them promptly to avoid further damage to the system.

- If you are using a manual air purger, it is important to remember to open and close the valve or bleeder screw as needed to release the air from the system. This should be done at regular intervals to ensure that the system is operating at its best.

- To avoid air getting trapped in the system in the first place, make sure to follow proper bleeding and purging procedures when filling and maintaining the system. This includes purging the system of air before turning it on for the first time and regularly bleeding the system to remove any trapped air.

- If you are unsure about how to properly install or maintain your air purger, it is always a good idea to consult with a qualified heating professional. They can provide guidance and recommendations to help you get the most out of your air purger and ensure that your system is running smoothly.

Final Words

In conclusion, an air purger is an essential component of a hydronic heating system. It helps to remove air from the system and maintain proper system function by ensuring that the system is operating at its best and prolonging the life of the equipment.

There are two main types of air purgers available: automatic and manual. Both types have their own benefits and drawbacks, and it is important to carefully consider the specific needs of the system before choosing the right air purger.

Proper installation and maintenance of the air purger is crucial to ensure optimal system performance and avoid issues with the system. By following the manufacturer’s instructions and regularly performing maintenance tasks, you can help to ensure that your air purger is working effectively and efficiently.

Also Carefully maintain the codes like 091.06.