Accidentally Cut Freon Line? Your Emergency Action Plan

A sudden hissing sound, a strange chemical smell, and the chilling realization—you’ve accidentally cut the freon line to your air conditioner. This is a scenario that sends a jolt of panic through any homeowner, and for good reason. A severed refrigerant line is not just an inconvenience; it’s a serious situation that requires immediate and correct action.

Cutting a freon line releases refrigerant into the atmosphere, posing risks to your health, your HVAC system, and the environment. This guide provides a clear, step-by-step emergency action plan. Follow these instructions carefully to ensure your safety and minimize damage to your property.

You'll Learn About

First Steps: What to Do Immediately After Cutting a Freon Line

Your immediate response is critical to mitigating the danger. In the moments after the line is cut, you must act quickly and decisively. Do not attempt to investigate the damage up close just yet; prioritize safety above all else.

1. Shut Down Your HVAC System

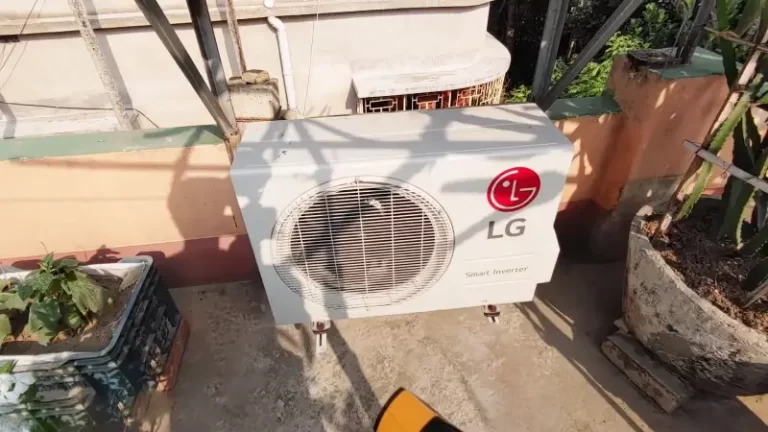

The very first thing you must do is cut all power to your air conditioning unit. Go to your home’s circuit breaker panel and find the breaker that controls the AC or heat pump. Switch it to the “OFF” position.

This is a crucial step. Allowing the system to continue running with a major leak can cause the compressor to seize up, leading to catastrophic and expensive failure. Turning off the power protects the most valuable component of your AC system.

2. Ventilate the Area Thoroughly

Refrigerant is heavier than air and will displace oxygen, especially in enclosed spaces like a basement or utility closet. Immediately open all nearby windows and doors to allow fresh air to circulate. If you have fans, use them to help dissipate the chemical cloud.

Proper ventilation is essential to prevent the buildup of refrigerant vapors, which can be harmful if inhaled in high concentrations. Do not remain in a poorly ventilated area where a leak is present.

3. Evacuate People and Pets

Ensure that all family members, especially children and pets, are moved away from the immediate vicinity of the leak. While refrigerant has low toxicity, direct inhalation can lead to dizziness, shortness of breath, and other health issues. Pets are particularly vulnerable due to their smaller size.

Keep everyone out of the area until it has been fully ventilated and deemed safe by a professional.

Identifying the Damaged Line and Understanding the Risks

Once you have taken the initial safety precautions, you can confirm that the issue is indeed a cut freon line. Understanding the signs and the associated dangers will reinforce why professional help is necessary.

Signs of a Cut Freon Line

The evidence of a severed refrigerant line is usually unmistakable. You will likely notice a combination of sensory cues that point directly to the problem.

You will almost certainly hear a loud hissing or gushing sound as the pressurized refrigerant escapes the line. You may also see a rapidly expanding cloud of white vapor. An oily residue is often left around the point of the break, which is the refrigerant oil escaping with the gas.

A distinct chemical odor is also a common indicator. The smell is often described as sweet and chloroform-like. If your house smells like a permanent marker or a similar chemical odor after the incident, it is almost certainly from the leaked refrigerant.

Health and Environmental Hazards

Exposure to leaking refrigerant poses several health risks. Direct contact with the rapidly expanding liquid can cause severe frostbite on the skin. The chemical is extremely cold as it depressurizes.

Inhaling the fumes can lead to refrigerant poisoning, with symptoms including headache, dizziness, nausea, and irritation of the eyes, nose, and throat. In severe cases or in confined spaces, it can lead to asphyxiation due to oxygen displacement.

Beyond the immediate health concerns, refrigerants are potent greenhouse gases. Releasing them into the atmosphere contributes to ozone depletion and climate change. Federal regulations strictly control the handling of these substances for this very reason.

Why DIY Repair Is Not an Option: Calling a Professional

In the age of online tutorials, the temptation to fix things yourself is strong. However, repairing a freon line is one job that must be left to a certified professional. Attempting a DIY fix is illegal, dangerous, and will likely cause more harm than good.

The Legality and Certification Requirements

In the United States, the Environmental Protection Agency (EPA) heavily regulates the handling of refrigerants under Section 608 of the Clean Air Act. Only technicians who have passed an EPA-administered test and are certified are legally allowed to purchase refrigerant and perform service on AC systems.

This regulation exists to protect the environment from the harmful effects of refrigerants. A homeowner cannot legally purchase the refrigerant needed to recharge the system after a repair.

Specialized Tools and Procedures

Repairing a refrigerant line involves much more than simply patching a pipe. A certified HVAC technician uses a specific set of expensive, specialized tools and follows a precise process to ensure a lasting and safe repair.

This process includes recovering any remaining refrigerant, properly repairing the line (usually by brazing a new section of copper), pressure testing the system with nitrogen to check for leaks, pulling a deep vacuum to remove all moisture and contaminants, and finally, recharging the system with the exact weight of the correct type of refrigerant. Failure to perform any of these steps correctly will lead to poor performance and eventual system failure.

DIY vs. Professional Repair: A Clear Choice

The table below outlines the stark differences between attempting a DIY repair and hiring a professional. The risks associated with a DIY approach far outweigh any perceived cost savings.

| Aspect | DIY Attempt | Professional HVAC Service |

|---|---|---|

| Legality | Illegal (violates EPA regulations) | Fully legal and compliant |

| Safety | High risk of frostbite, chemical exposure, and fire | Trained professionals use safety equipment |

| Tools Required | Lacks necessary tools (vacuum pump, gauges, recovery unit) | Uses specialized, calibrated equipment |

| Effectiveness | Almost certain to fail; introduces contaminants | Permanent, high-quality repair |

| System Health | Leads to compressor damage and premature failure | Protects and extends the life of the HVAC system |

| Cost Outcome | Results in much higher costs from component failure | Upfront cost prevents larger future expenses |

The Professional Repair Process: What to Expect

When you call a certified HVAC technician, they will follow a systematic process to get your air conditioner back online safely. Understanding these steps will help you know what to expect and ensure the job is done right.

Step 1: Assessment and Leak Location

The technician will first assess the situation and confirm the location of the break. They will inspect the copper lines for any other potential weak spots or damage that could cause future problems.

Step 2: Line Repair or Replacement

The damaged section of the line must be professionally repaired. This is typically done by cutting out the broken piece and brazing (a form of high-temperature soldering) a new piece of copper tubing in its place. This creates a permanent, leak-proof seal.

Step 3: System Evacuation

This is one of the most critical steps that is impossible to do without the right tools. Once the line is sealed, the technician will connect a vacuum pump to the system. This pump removes all the air, and more importantly, all the moisture that entered the system when the line was open.

Leaving moisture in the system will create acids that corrode internal components and destroy the compressor over time. A deep vacuum must be pulled to a specific level (measured in microns) to ensure all contaminants are gone.

Step 4: Recharging with Refrigerant

After a successful evacuation, the technician will recharge the system with a fresh supply of the correct type of refrigerant. Every HVAC system has a specific charge amount, measured by weight. The technician will use a digital scale to add the precise amount of freon required for your unit.

Undercharging or overcharging the system will reduce efficiency, increase electricity bills, and put a severe strain on the compressor. This is why a precise measurement is essential.

Step 5: System Testing

Finally, the technician will turn the system back on and perform a series of tests. They will check operating pressures, temperatures, and the overall cooling performance to ensure everything is working exactly as it should. This confirms the repair was successful and the system is operating efficiently.

Understanding the Costs of Repair

The cost to repair a cut freon line can vary significantly based on several factors. While it is an unexpected expense, it’s a necessary investment in the health of your HVAC system.

Factors Influencing the Final Bill

The primary factors that will determine the cost include the location and accessibility of the damaged line, the type of refrigerant your system uses, and the amount of refrigerant needed to fully recharge it. The price of refrigerants like R-410A or the older R-22 can fluctuate.

Generally, you can expect to pay for the initial service call fee, labor charges for the repair and testing, and the cost of the refrigerant itself. A straightforward repair could cost a few hundred dollars, while a more complex break or one requiring a large amount of expensive refrigerant could be significantly more.

Long-Term System Damage and How to Prevent It

A cut freon line is more than an immediate problem; it can have lasting consequences for your HVAC system if not handled correctly. The sudden loss of refrigerant and the introduction of outside air can set off a chain reaction of internal damage.

The Silent Killer: Compressor Damage

Refrigerant doesn’t just cool the air; it also carries a special oil that lubricates the compressor, the heart of your AC system. When all the refrigerant leaks out, the compressor loses its lubricant. If the system is allowed to run even for a short time in this state, the lack of lubrication will cause extreme friction and heat, leading to the mechanical failure of the compressor.

This is why immediately shutting off the power is so important. A compressor replacement is one of the most expensive HVAC repairs, often costing thousands of dollars.

Contaminants and Corrosion

When the sealed system is opened to the atmosphere, air and humidity rush in. Moisture is the enemy of an HVAC system. When it mixes with refrigerant and oil, it forms corrosive acids that slowly eat away at the internal windings of the compressor and other metal parts, causing a slow and premature death for your system.

This long-term, hidden damage is precisely what a professional’s vacuuming process prevents. It’s a non-negotiable step to ensure the longevity of the repair and the system as a whole.

How to Prevent Future Accidents

Preventing a similar incident in the future comes down to awareness and simple precautions. Taking a few extra minutes before doing yard work can save you from a major headache and expense.

Landscaping and Yard Work Awareness

Most freon lines are cut accidentally during landscaping activities. Be extremely careful when using a lawnmower, string trimmer, or edger near your outdoor condenser unit. The soft copper lines are often exposed as they run from the unit into your house.

Before you begin any digging or heavy yard work, physically locate your refrigerant lines. Consider adding a small, protective barrier or clearly marking their location with flags to remind yourself where they are. This simple act of mindfulness is the best prevention.

Conclusion: A Serious Problem with a Clear Solution

Accidentally cutting a freon line is a serious and stressful event. However, by taking immediate and appropriate action, you can protect yourself, your family, and your expensive HVAC equipment. The solution is straightforward: shut off the power, ventilate the area, and call a certified professional.

Do not attempt to repair the line yourself. The risks are too high, and the potential for causing further, more expensive damage is almost guaranteed. A professional technician has the skills, tools, and legal authority to perform the repair safely and effectively, ensuring your home remains cool and comfortable for years to come.