Snow Blower Choke Symbol Solved: The #1 Guide to a Perfect Start

Nothing is more frustrating than a snow blower that refuses to start when a blizzard has just buried your driveway. Often, the culprit isn’t a major mechanical failure but a simple misunderstanding of one crucial control: the choke lever and its cryptic symbol.

That little icon, often looking like a simple line drawing, is the key to enriching the fuel mixture for a cold engine start. Misinterpreting it means you’re either starving the engine of the fuel it needs or flooding it entirely. This guide deciphers that universal symbol once and for all, ensuring you get a powerful, reliable start every single time.

You'll Learn About

Decoding the Mystery: What Exactly Is a Snow Blower Choke?

Before understanding the symbol, it’s essential to know what the choke mechanism does. Think of it as a temporary boost for a cold engine. Internal combustion engines require a very specific ratio of air and fuel to ignite and run efficiently.

When an engine is cold, gasoline vaporizes poorly. This leads to a “lean” mixture—too much air and not enough fuel vapor.

The choke plate is a small flap located in the carburetor’s throat that, when activated, partially closes off the air intake.

This restriction creates a vacuum effect that pulls more gasoline from the carburetor’s fuel bowl into the engine’s combustion chamber. This creates a “rich” fuel mixture, which has a higher concentration of gasoline that is much easier to ignite in cold conditions. Once the engine warms up, it can vaporize fuel properly, and the choke is no longer needed.

The Universal Snow Blower Choke Symbols Explained

While some manufacturers use text like “START” and “RUN,” most rely on universal symbols to overcome language barriers. Unfortunately, these symbols can be confusing. Here is the definitive breakdown of what they mean.

The core concept is simple: one symbol represents a CLOSED air passage (choke on), and the other represents an OPEN air passage (choke off). The icon is a simplified diagram of the choke plate inside the carburetor.

The “Choke ON” (Closed) Symbol: This is the position for starting a cold engine. The symbol typically shows a vertical line directly connected to two angled lines that form a closed or nearly closed “V” shape on its side. It signifies that the choke plate is closed, restricting airflow.

The “Choke OFF” (Open/Run) Symbol: This is the position for a warm, running engine. The symbol shows a vertical line with a clear gap in the middle where it meets the angled lines, representing an open “V” shape. This signifies that the choke plate is fully open, allowing maximum airflow.

To make this even clearer, here is a quick-reference table that breaks down everything you need to know at a glance.

| Symbol | Lever Position Name | What It Does | When to Use It |

|---|---|---|---|

| ■ (Represents Closed Symbol) | Choke ON / START | Restricts air intake, creating a rich fuel mixture. | Only for starting a completely cold engine. |

| □ (Represents Open Symbol) | Choke OFF / RUN | Allows full airflow for an efficient fuel mixture. | After the engine has warmed up for 30-60 seconds. |

Step-by-Step: The Perfect Choke Start Every Time

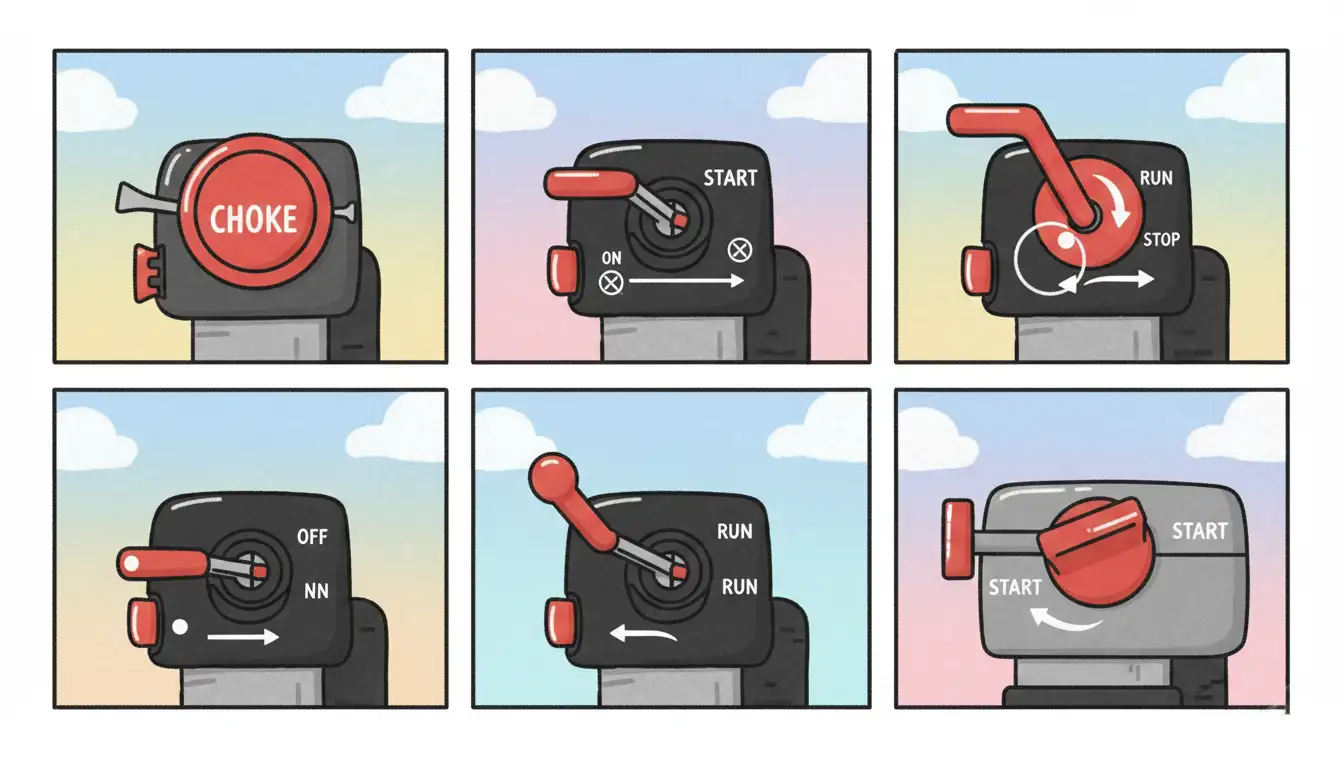

Using the choke correctly involves more than just flipping a switch. It’s a sequence of events timed to match the engine’s needs as it warms up from cold. Follow these steps precisely for a flawless start.

Step 1: Locate and Set the Choke. Before you do anything else, identify the choke lever. Now that you understand the symbols, move the lever to the “Choke ON” (Closed) position. This is the single most important step for a cold start.

Step 2: Engage Other Controls. Set the throttle to the “Fast” or rabbit symbol position. Turn the ignition key or switch to the “ON” position. If your snow blower has a fuel shut-off valve, ensure it is open.

Step 3: Prime the Engine. Locate the primer bulb, a small, soft plastic button. Press it firmly two to three times. This squirts a small amount of raw fuel directly into the carburetor, giving the engine an initial shot of fuel to ignite.

Step 4: Pull the Starter Cord. Grab the starter handle and pull the cord with a firm, smooth motion. The engine should start, though it may sound a bit rough or uneven at first. This is normal for an engine running on a rich mixture.

Step 5: The Critical Warm-Up. Let the engine run with the choke fully on for about 15 to 30 seconds. This is a critical period where the engine components begin to heat up, allowing fuel to vaporize more effectively.

Step 6: Gradually Disengage the Choke. After the brief warm-up, slowly begin moving the choke lever towards the “Choke OFF” (Open/Run) position. You may need to do this in stages. If the engine starts to sputter or die, you’ve moved it too quickly. Move it back towards the “ON” position slightly and give it more time.

Step 7: Full Run Position. Once the engine is running smoothly without any sputtering, move the choke lever all the way to the “Choke OFF” position. Your snow blower is now ready to tackle the snow.

Troubleshooting: When Your Engine’s Choke System Fights Back

Even with a perfect understanding of the choke symbol, problems can arise. These issues often point to deeper underlying conditions within the fuel system. How the engine behaves with the choke is one of the best diagnostic tools you have.

An engine that refuses to run properly without the choke is sending a clear signal: it is not receiving enough fuel through its normal fuel circuits. When you activate the choke, you are manually compensating for this fuel starvation. If your snow blower only runs with the choke on, it is a tell-tale sign of a problem.

Sometimes the issue is less severe, and the engine seems to find a sweet spot in the middle. If you find your snowblower runs better on half choke, it means the main fuel jet is partially, but not completely, clogged. It’s a warning sign that a full blockage is likely imminent.

The most common scenario is an engine that starts fine but then begins to sputter and cough as soon as you move the lever. If your snowblower runs rough without choke, the carburetor’s internal passages are almost certainly gummed up from old fuel. This prevents a smooth transition from the rich starting mixture to the leaner running mixture.

The “Secret” Language of Your Engine: Listening for Choke Clues

Your snow blower communicates its state through sound and even smoke. Learning to interpret these signals can tell you exactly what’s happening with the fuel mixture and whether the choke is set correctly.

When the choke is left on too long after the engine is warm, the fuel mixture becomes overly rich. The engine will begin to sputter and run unevenly. You may also see a telling puff of black smoke coming from the exhaust. This black smoke is unburnt fuel, a clear sign that you are wasting gas and creating harmful carbon buildup on internal components like the spark plug and piston head.

Conversely, a properly running engine in the “Choke OFF” position should have a smooth, consistent hum. The throttle response will be crisp and immediate. Any hesitation or sputtering when you try to engage the auger is a sign that the engine might need a little more warm-up time or that the choke was disengaged too soon.

Pro-Tip: Temperature and Altitude Dictate Choke Use

The choke isn’t a one-size-fits-all control. Environmental conditions play a massive role in how you should use it. On a bitterly cold day, say 0°F (-18°C), the metal engine block is colder and fuel vaporizes much less efficiently. In these conditions, you may need to let the engine warm up with the full choke for closer to a minute.

In contrast, if you are restarting a warm engine—for instance, after you stopped for a few minutes to clear a clog—you should not use the choke at all. The engine is already warm enough to vaporize fuel correctly, and engaging the choke will immediately flood it, making it very difficult to start.

Altitude also has an impact. Air is less dense at higher altitudes, which naturally creates a richer fuel-to-air mixture. In these locations, you may need less choke time, or on marginally cool days, you might not need the choke at all.

Beyond the Symbol: Protecting Your Fuel System

The root cause of nearly all choke-related running problems is old, degraded fuel. Modern gasoline can start to break down in as little as 30 days. As it decays, it forms varnish and gummy deposits that clog the incredibly small passages inside the carburetor.

The most important preventative maintenance task you can perform is to use a high-quality fuel stabilizer with every single tank of gas. This additive prevents fuel degradation and keeps the carburetor’s tiny jets and passages clean. This single, inexpensive step can prevent 90% of starting and running issues.

Furthermore, at the end of the season, never store your snow blower with untreated gas in the tank. Either run the engine completely dry to empty the tank and carburetor, or fill the tank with fuel treated with an appropriate amount of stabilizer designed for long-term storage.

Conclusion: From Confused to Confident

The snow blower choke symbol is no longer a mystery. It is a simple diagram representing the choke plate’s position—closed for a cold start and open for a warm engine. By understanding this fundamental concept, you transform the starting process from a game of chance into a reliable, repeatable procedure.

Remember the sequence: set the choke to ON (Closed), prime the engine, start it, allow a brief warm-up, and gradually move the choke to OFF (Run). Listening to your engine and watching for signs like black smoke will make you an expert in fine-tuning the process. By combining this knowledge with proper fuel maintenance, you ensure your machine will roar to life on the coldest winter morning, ready to conquer the snow.