Tecumseh Points to Electronic Ignition: The Ultimate No-Spark Fix!

There’s a familiar frustration for owners of classic equipment powered by older Tecumseh engines. You pull the starter cord on your trusted snow blower or lawn mower, expecting the familiar roar, but get nothing. Or worse, it sputters, coughs, and dies, leaving you with a sore arm and an unfinished job. The culprit behind this maddening unreliability is often a tiny, antiquated set of mechanical components: the points and condenser ignition system.

For decades, this system was the standard, but its mechanical nature is its greatest weakness. Over time, the points wear down, corrode, and fall out of adjustment, leading to a weak or nonexistent spark. This guide will walk you through the definitive solution—a conversion to a modern, solid-state electronic ignition—transforming your hard-to-start engine into a model of reliability.

You'll Learn About

The Unseen Enemy: Why Your Tecumseh’s Points System Is Failing You

To appreciate the solution, one must first understand the problem. The points and condenser system is a mechanical switch. As the flywheel spins, a cam opens and closes a set of breaker points, telling the ignition coil when to release its high-voltage spark. The condenser’s job is to absorb excess electricity to prevent the points from arcing and burning out prematurely.

This mechanical ballet is prone to failure. The constant friction wears down the rubbing block on the points, changing the gap and altering the ignition timing. Moisture and dirt can cause corrosion on the point contacts, preventing a clean electrical connection and resulting in a feeble, yellow spark instead of a crisp, blue one.

The Domino Effect of a Failing Points System

A weak spark leads to a cascade of problems. Fuel doesn’t burn completely, leading to carbon buildup on the spark plug and in the combustion chamber. This results in hard starting, rough idling, poor fuel economy, and a noticeable loss of power. For many, this means constant tinkering, cleaning, and adjusting—a frustrating cycle for a piece of equipment you just want to work.

Troubleshooting these issues can be a headache. A “no-spark” condition could be worn points, a failed condenser, a bad coil, or even a faulty wire. The process of elimination often involves removing the heavy flywheel just to access and inspect these small, hidden components, a task that can be daunting for many owners.

The Ultimate Upgrade: Breathing New Life into Your Engine with Electronic Ignition

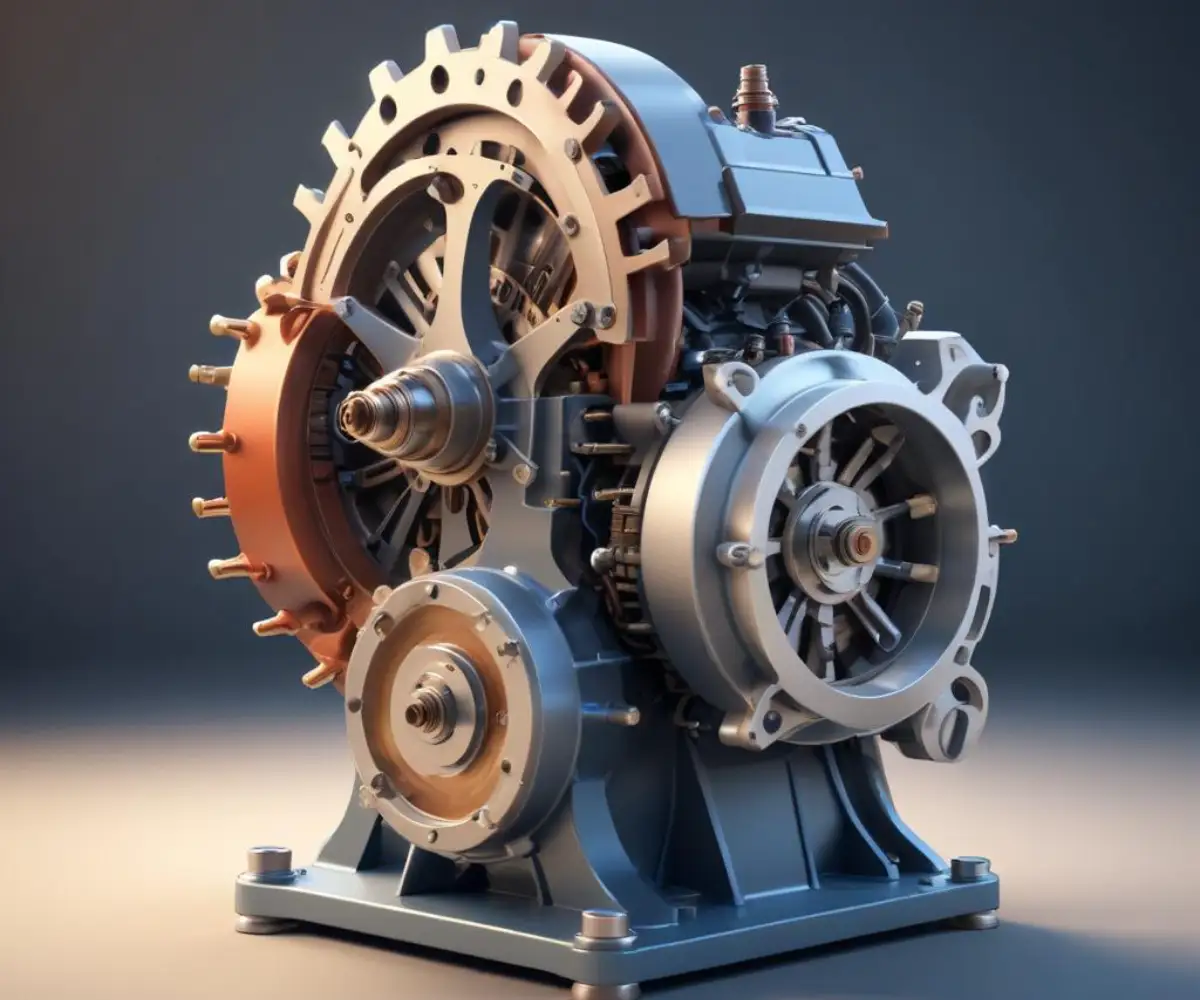

The solution is to eliminate the mechanical points and condenser entirely and replace them with a solid-state electronic ignition module. This small, sealed unit is a modern marvel of simplicity and reliability. It contains no moving parts, making it impervious to the wear, corrosion, and moisture that plague older systems.

This module effectively replaces the points, acting as a high-speed, non-mechanical switch. Triggered by the flywheel’s powerful magnets, it tells the coil to fire with perfect timing, every single time. The result is a powerful, consistent, and hot spark that dramatically improves every aspect of your engine’s performance. The benefits are immediate and substantial.

Why an Electronic Ignition Conversion is the Best Upgrade for Your Tecumseh

The advantages of this conversion are numerous. You’ll experience significantly easier starting, often on the first or second pull, even in cold or damp conditions. The engine will run smoother, idle more consistently, and produce more power. Many users also report improved fuel efficiency due to more complete combustion.

Perhaps the biggest benefit is the elimination of maintenance. Once installed, the electronic ignition module is a “set it and forget it” component. There are no more points to clean or adjust, making it a permanent fix for your ignition woes. Considering the reliability, it’s a small investment that pays huge dividends, much like reviewing your Maytag water softener reviews ensures long-term home appliance dependability.

Your Step-by-Step Guide: Converting Tecumseh Points to Electronic Ignition

This conversion is a straightforward process that can be completed with basic hand tools. Follow these steps carefully to ensure a successful upgrade and bring your Tecumseh engine into the modern era.

1. Safety and Preparation

Before beginning any work, safety is paramount. Disconnect the spark plug wire from the spark plug and secure it away from the engine to prevent any accidental starts. It’s also wise to drain the fuel tank to avoid spills. Gather your tools, which will typically include a socket set, a flywheel puller, feeler gauges, and potentially a torque wrench for reassembly.

2. Accessing the Ignition System

You must first remove the engine’s outer metal cover, often called the blower housing or shroud. This is usually held on by several bolts. This will expose the top of the flywheel. You will also need to remove the starter cup or screen from the center of the flywheel.

3. Removing the Flywheel

This is often the most challenging step. The flywheel is held onto the crankshaft by a large central nut and is seated on a taper. After removing the nut, you will need a flywheel puller to safely remove it. Never strike the flywheel or crankshaft with a hammer, as this can cause severe damage. The puller uses threaded bolts that screw into holes on the flywheel, and a central bolt pushes against the crankshaft to pop the flywheel loose.

4. Removing the Points and Condenser

With the flywheel removed, you will see the old ignition system. The points and condenser are typically mounted together on a plate. Carefully unscrew them and disconnect their wires from the ignition coil. You can completely remove these components as they will no longer be used. Now is an excellent time to clean any dirt or oil from the area.

5. Installing the New Electronic Module

The new electronic ignition module will replace the function of the points. While some kits replace the entire coil, many popular modules work with your existing coil. Typically, one wire from the module connects to the small terminal on your coil where the points wire was, and the other wire connects to a good ground on the engine block. Mount the module securely in a convenient location away from excessive heat.

6. The Critical Air Gap

If you are replacing the entire coil with a new solid-state version, setting the air gap is the most critical step for proper function. Rotate the flywheel so the magnets are aligned with the coil. Loosen the coil’s mounting bolts and place a non-magnetic feeler gauge or a standard business card (which is approximately 0.010 inches thick) between the magnets and the coil legs. The magnets will pull the coil against the card; tighten the mounting bolts securely and then remove the card.

7. Reinstalling the Flywheel and Final Checks

Before reinstalling the flywheel, inspect the flywheel key—a small metal piece that aligns the flywheel on the crankshaft. If it is even slightly damaged or sheared, replace it. The key’s integrity is crucial for correct ignition timing. Slide the flywheel back onto the crankshaft, ensuring the key is properly seated. Torque the flywheel nut to the manufacturer’s specifications. Reconnect the stop switch wire, reinstall the blower housing, and reconnect the spark plug wire.

Beyond the Basics: Pro Tips for a Flawless Conversion

Even with a straightforward installation, issues can arise. Understanding a few key details can save you from frustration and ensure your engine runs perfectly after the conversion.

The Unsung Hero: The Flywheel Key

Many people mistakenly believe the flywheel key’s only job is to hold the flywheel in place. Its primary function is to precisely time the ignition by aligning the flywheel’s magnets with the coil at the exact right moment. If you strike an object with your mower blade or snow blower auger, the force can partially shear this soft metal key, knocking the ignition timing off by a few degrees. With a points system, you might not notice, but with the precise timing of an electronic module, a sheared key can prevent the engine from starting or cause it to run poorly. Always use a new key when reinstalling the flywheel.

Troubleshooting: What if There’s Still No Spark?

If you’ve completed the conversion and still have no spark, don’t panic. First, re-check your air gap if you installed a new coil. An incorrect gap is a common cause of failure. Next, ensure all your wiring connections are clean and tight, especially the ground wire for the module. Finally, disconnect the engine’s main “kill” or “stop” switch wire. A faulty switch can ground out the ignition, preventing a spark. This is a crucial diagnostic step, similar to identifying why an electric wall heater is glowing red, as it isolates the problem to a specific component.

Points & Condenser vs. Electronic Ignition: A Head-to-Head Comparison

To fully appreciate the upgrade, a direct comparison is helpful. The table below highlights the significant advantages of converting to a modern electronic ignition system.

| Feature | Points & Condenser Ignition | Solid-State Electronic Ignition |

|---|---|---|

| Reliability | Low to Moderate. Prone to wear and environmental factors. | Very High. No moving parts to wear out. |

| Maintenance | Requires regular cleaning, gapping, and replacement. | None. It is a “set it and forget it” component. |

| Spark Quality | Degrades over time, leading to a weaker spark. | Consistently strong and hot spark. |

| Starting Ease | Can become difficult, especially in cold or damp weather. | Significantly improved, often starting on the first pull. |

| Long-Term Cost | Requires periodic replacement of parts and can involve labor costs. | A one-time purchase with no future costs. |

| Weather Resistance | Highly susceptible to moisture and dirt. | Sealed unit is impervious to environmental conditions. |

Is the Electronic Ignition Upgrade Worth It for Your Tecumseh Engine?

Absolutely. For a relatively small investment of time and money, converting from points to electronic ignition is arguably the single best upgrade you can make to an older Tecumseh engine. It solves the most common point of failure and transforms an often-frustrating piece of equipment into a reliable workhorse. The peace of mind that comes from knowing your engine will start when you need it is invaluable.

This project doesn’t just fix a problem; it modernizes your engine, extending its life and improving its overall performance. While the upgrade is simple, the financial aspect is also manageable. Understanding the cost of a permit to replace an electrical panel puts into perspective how affordable and impactful this small engine project truly is. By taking on this task, you are ensuring your equipment remains a valuable and dependable asset for years to come.