No Fuel in Carburetor Bowl? Your Ultimate Fix Guide Now

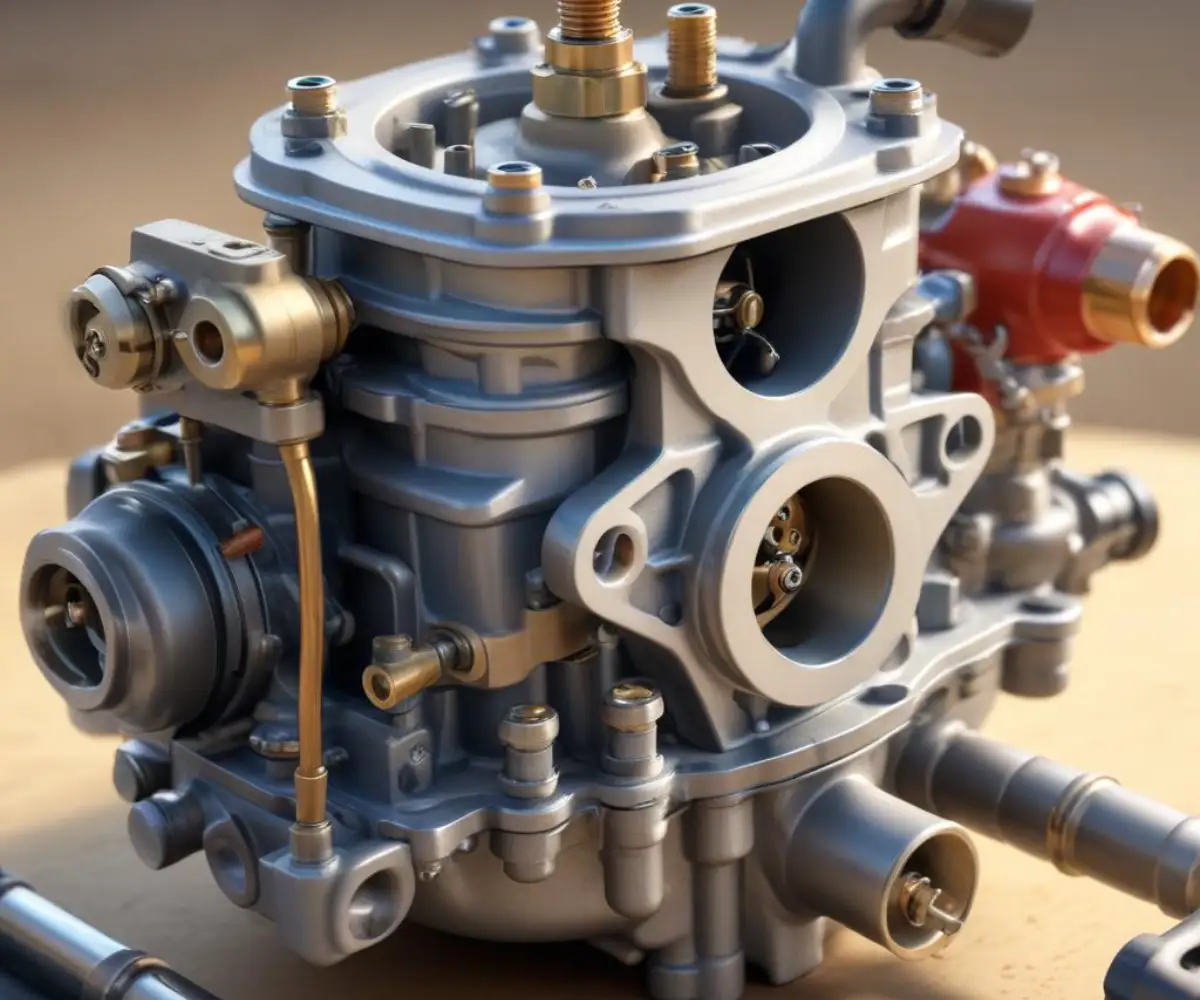

There’s nothing more frustrating than an engine that refuses to start. You’ve checked the spark, you know there’s gas in the tank, but after a quick inspection, you discover the heart of the problem: a bone-dry carburetor bowl. This complete lack of fuel, known as fuel starvation, is a common issue that can bring any small engine to a halt.

Understanding why there’s no fuel in the carburetor bowl is the first step toward a solution. This guide will walk you through a systematic approach to diagnose the cause, from the simplest oversights to the most common internal carburetor failures, and provide clear, actionable steps to get your engine running smoothly again.

You'll Learn About

Why Is My Carburetor Bowl Empty? The Root Causes

A small engine’s fuel system is a relatively simple path: fuel travels from the tank, through a fuel line and filter, and into the carburetor, where it’s mixed with air. A problem at any point along this path can prevent gasoline from reaching the carburetor bowl. The most common culprits fall into three categories: fuel supply issues, blockages, and internal carburetor faults.

An often-overlooked but critical component is the fuel cap vent. Fuel tanks need to breathe; as fuel is drawn out, air must come in to replace it. If the tiny vent hole in the fuel cap becomes clogged with dirt or debris, it can create a vacuum in the tank, effectively stopping the flow of gasoline no matter how clean the rest of the system is.

Common Fuel Flow Obstructions

Before assuming the carburetor is the problem, it’s essential to rule out simpler issues. A faulty or closed fuel shut-off valve can easily be mistaken for a more complex problem. Likewise, a clogged fuel filter is one of the most frequent causes of fuel starvation. These filters are designed to trap debris and can become completely blocked over time, especially if the fuel is old or contaminated. Lastly, the fuel line itself can be the source of the blockage, either from being kinked, cracked, or internally deteriorated.

Step-by-Step Diagnosis: Finding the Fuel Flow Culprit

A methodical approach will save you time and frustration. Start with the easiest checks and work your way toward the more complex components. This process will systematically eliminate potential causes until you pinpoint the exact reason for the fuel stoppage.

First, confirm the basics. Ensure there is fresh, clean fuel in the tank and that the fuel shut-off valve is in the “ON” position. Next, loosen the gas cap to see if a vacuum lock is the issue; if you hear a faint whoosh of air entering the tank, a clogged vent is likely your problem.

Testing Fuel Flow to the Carburetor

The most definitive diagnostic step is to verify whether fuel is reaching the carburetor. Place a catch pan under the carburetor, carefully disconnect the fuel line from the carburetor’s inlet fitting, and turn the fuel valve on. Fuel should flow steadily from the line. If it only trickles or doesn’t flow at all, the problem lies somewhere between the tank and the end of that fuel line.

If you have confirmed a lack of flow, the next step is to inspect the fuel filter and the line itself. If fuel flows freely when the line is disconnected from the carburetor, you have successfully isolated the problem to an internal carburetor issue.

The Ultimate Fix: How to Get Fuel Flowing Again

Once you’ve diagnosed the source of the fuel starvation, the solution is often straightforward. Addressing issues upstream of the carburetor involves simple parts replacement, while an internal carburetor problem typically requires a thorough cleaning of a specific component.

If your diagnosis pointed to a clogged fuel filter or a damaged fuel line, the solution is simple replacement. These parts are inexpensive and readily available. Always use fuel lines designed for the type of fuel your engine uses, as modern ethanol-blended gasoline can degrade older rubber lines from the inside out.

Unsticking the Float Needle Valve: The #1 Culprit

If fuel reaches the carburetor but doesn’t enter the bowl, the problem is almost always a stuck float needle valve. The float system is designed to act as a dam; as the bowl fills, the float rises and presses a small, rubber-tipped needle into a brass seat, shutting off the fuel flow. When old fuel evaporates, it leaves behind a sticky varnish that can glue this needle in the closed position.

Sometimes, a few gentle taps on the side of the carburetor bowl with the handle of a screwdriver can be enough to vibrate the needle free. If that doesn’t work, you’ll need to remove the bowl. Once the bowl is off, you can carefully remove the pin holding the float in place. This will allow you to lift the float and the attached needle out for cleaning.

Use carburetor cleaner and a soft tool like a cotton swab to clean the needle and, more importantly, the brass seat it rests in. Never use a hard metal object to clean the seat, as scratches can cause the opposite problem: a persistent leak. Once clean, reassemble the float and needle, reattach the bowl, and test for fuel flow.

A stuck-open needle valve will cause fuel to continuously flood the carburetor, a situation that often results in gas leaking from the vent hole. If you’ve ever faced this issue, the cause is the same component, just failing in the opposite way. You can learn more about this specific problem in our guide on fixing a Tecumseh carburetor leaking from the vent hole.

Prevention is Better Than a Cure: Keeping Your Carburetor Healthy

Consistent maintenance is the key to preventing fuel delivery problems. The varnish and corrosion that cause most carburetor issues are a direct result of old, untreated fuel. Taking a few simple preventative steps can save you from future headaches.

Using fresh fuel is paramount. Gasoline, especially fuel containing ethanol, can begin to break down in as little as 30 days. For equipment that is used infrequently, such as a snowblower, always use a quality fuel stabilizer to prolong the life of the gasoline and prevent varnish buildup. A properly maintained engine should run smoothly; if you notice it only runs well on half choke, this is a classic sign of a partially clogged jet, indicating a need for cleaning. This is often a precursor to more severe fuel issues, a topic we cover in depth in our article about why a snowblower runs better on half choke.

| Maintenance Task | Frequency | Why It’s Important |

|---|---|---|

| Use Fresh Fuel (Less than 30 days old) | Every Use | Prevents the formation of sticky varnish and deposits that clog small passages. |

| Add Fuel Stabilizer | Each Refill (for stored equipment) | Extends the life of gasoline, prevents phase separation, and inhibits corrosion. |

| Inspect/Replace Fuel Filter | Annually or as needed | Ensures a clean, unrestricted supply of fuel reaches the carburetor. |

| Inspect Fuel Lines | Annually | Checks for cracks, kinks, or softness that could lead to leaks or blockages. |

| Run Carburetor Dry | Before Long-Term Storage | Removes all fuel from the bowl, eliminating the primary source of varnish buildup. |

When to Call a Professional

While most fuel delivery issues can be solved with basic tools and a bit of patience, there are times when it’s best to seek professional help. If you have attempted to clean the carburetor and the problem persists, or if you’ve damaged a component like a stripped screw or a torn gasket during disassembly, it may be time to consult a mechanic.

A professional has the experience and specialized tools, like ultrasonic cleaners, to thoroughly restore a carburetor to factory specifications. If you’re weighing the options, understanding the potential expense can help. For a detailed breakdown, consider reading our article on the cost to clean a snowblower carburetor, which compares professional service prices with the DIY approach.

Ultimately, solving the mystery of an empty carburetor bowl is a process of elimination. By working methodically from the fuel tank to the carburetor’s internal components, you can accurately diagnose and fix the fuel starvation issue. A clean and well-maintained fuel system is the key to a reliable, easy-starting engine.