Snowblower Gearbox Grease: The #1 Mistake Destroying Your Machine

That horrible grinding sound from the front of your snowblower is more than just an annoyance. It’s the sound of metal-on-metal destruction, a clear signal that the heart of your machine—the auger gearbox—is in serious trouble. Neglecting this critical component is the single most expensive mistake a snowblower owner can make.

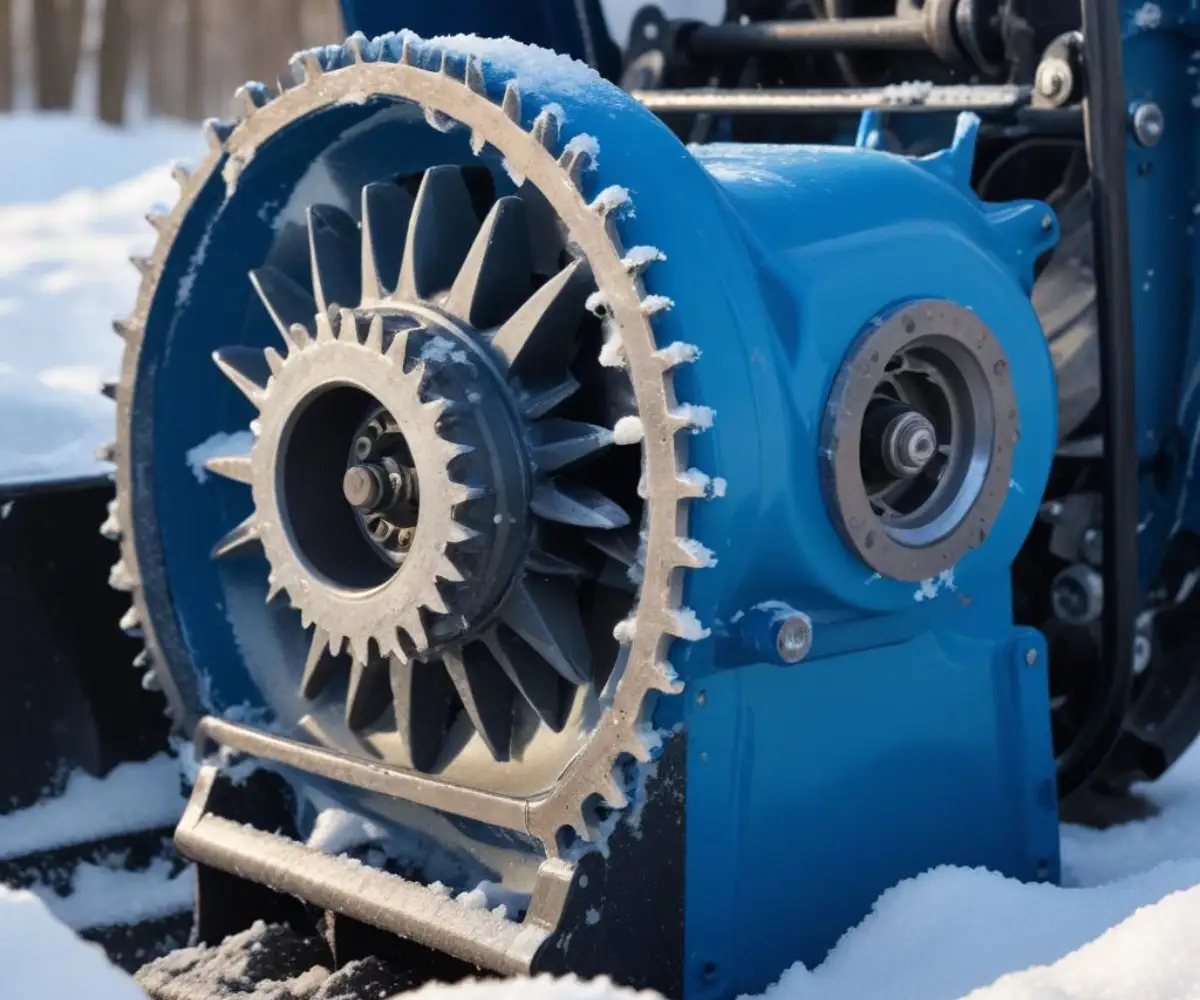

The auger gearbox is a powerhouse, translating engine power into the immense torque needed to chew through heavy, wet snow and ice. But inside that small housing, immense pressure and friction are constantly at play. The only thing standing between smooth operation and catastrophic failure is a few ounces of specialized grease.

You'll Learn About

Why Your Snowblower’s Gearbox is a Ticking Time Bomb

Many owners assume the gearbox is a sealed, “maintenance-free” unit. This is a dangerous misconception. Over time, seals can fail, gaskets can dry out, and condensation can introduce water into the housing, contaminating the lubricant. This leads to a breakdown of the grease’s protective properties.

Once the grease fails, the worm gear and bronze gear inside begin to wear at an accelerated rate. Instead of gliding smoothly, they grind against each other, shearing off microscopic metal particles. This creates a destructive slurry that further hastens the gearbox’s demise, leading to a costly repair bill that could have been easily avoided.

Grease vs. Oil: The Critical Difference Most Owners Get Wrong

A common point of confusion is whether to use grease or gear oil. While some older, cast-iron gearboxes were designed for gear oil, the vast majority of modern snowblowers use a specific type of grease. Using the wrong one can be just as bad as using none at all.

Thick, tacky grease, like standard wheel bearing grease, is unsuitable for a snowblower gearbox. In the cold, it becomes too stiff, and the gears will simply carve a path through it, flinging the grease to the sides of the case where it does nothing to lubricate the moving parts. Conversely, some gear oils may be too thin and leak out past the seals. This is a nuanced topic, and for some machines like Ariens models, understanding the specifics of auger gearbox oil is crucial to prevent damage.

The Telltale Signs of Gearbox Grease Failure

Catching a problem early can save you from a complete gearbox replacement. Be alert for these warning signs. A sudden increase in grinding or whining noises from the auger housing is the most obvious symptom. You might also notice the augers struggling to turn or stopping completely in heavy snow, even when the engine is running strong.

If you suspect a problem, you can perform a quick check. With the machine off and the spark plug disconnected, try to turn the augers by hand. If you feel excessive play, notchiness, or hear clunking sounds, it’s a strong indication of internal wear. Visually inspecting the grease by removing the fill plug can also reveal metal shavings, a sure sign of gear destruction.

What Happens When You Use the Wrong Lubricant?

Using an incorrect lubricant can lead to a host of problems. A grease that is too thick will cause “channeling,” where the gears push the lubricant aside, leading to dry operation and overheating. This heat can break down the grease further and accelerate wear on the bronze gear.

Some gear oils, particularly those with a GL-5 rating, contain sulfur-based additives that can be corrosive to the soft bronze gears found in many snowblower gearboxes. This chemical reaction can slowly eat away at the gear teeth, leading to premature failure. It’s critical to use a lubricant that is compatible with “yellow metals” like bronze.

Choosing the Right Snowblower Gearbox Grease: A Complete Guide

Selecting the correct grease is not just a suggestion; it’s a requirement for the long-term health of your machine. The goal is to find a lubricant that is fluid enough to flow and coat the gears in extreme cold but thick enough to not leak out of the seals. This unique consistency is often referred to as a “semi-fluid” or “flowable” grease.

The most commonly recommended type is an NLGI #00 grease. This “double-naught” grade strikes the perfect balance for snowblower gearboxes. It’s thin enough to slump back into the path of the gears after being displaced, ensuring continuous lubrication even in sub-zero temperatures.

Understanding Grease Types: NLGI Grades and Base Oils

Grease is essentially a combination of base oil, thickeners (like lithium soap), and additives. The NLGI (National Lubricating Grease Institute) grade indicates the grease’s consistency, ranging from 000 (fluid) to 6 (very hard). For snowblowers, you will almost always need a very soft grease like #00 or sometimes #0.

Beyond the grade, the type of base oil and additives matter. A synthetic base oil will offer superior performance in extreme cold. Look for greases with Extreme Pressure (EP) additives, but ensure they are non-corrosive to bronze gears. Shell Alvania and Lubriplate are brands often cited as being OEM-equivalent for many models.

The Best Grease for Your Snowblower Gearbox

While your owner’s manual is the ultimate authority, certain products have become industry standards for their proven performance. Products specifically labeled as “Snowblower Auger Grease” or a high-quality “00” grease are your safest bets. For specific models like a John Deere 832 snowblower, checking dealer recommendations can also provide clarity.

The following table breaks down common lubricant choices and their suitability for snowblower auger gearboxes.

| Lubricant Type | NLGI Grade | Common Use | Suitability for Snowblower Gearbox |

|---|---|---|---|

| Semi-Fluid EP Grease | 00 | Centralized lube systems, enclosed gearboxes | Excellent – The most commonly recommended type. |

| Low-Temp Lithium Grease | 0 or 1 | Chassis lubrication, some bearings | Good – Can work but may be slightly too thick in extreme cold. |

| Standard Multi-Purpose Grease | 2 | Wheel bearings, general chassis | Poor – Too thick; will cause channeling and starvation. |

| Synthetic Gear Oil (75W-90) | N/A | Automotive differentials, transmissions | Use with Caution – Only if specified by manufacturer; may leak from seals. |

Step-by-Step Guide: How to Replace Your Snowblower Gearbox Grease

Replacing the grease is a straightforward maintenance task that can be done with basic tools. This should be performed at least every few seasons, or immediately if you suspect contamination or leaks. An annual check is a good practice.

Tools and Materials You’ll Need

Before you begin, gather your supplies. You will need a socket set, a putty knife or scraper for the old gasket, a clean drain pan, shop rags, and of course, the correct replacement grease. A tube of RTV gasket maker or a pre-cut gasket will be needed for reassembly.

A suction gun or a large syringe can be very helpful for removing the old grease if the gearbox doesn’t easily split. Running the snowblower for a few minutes before starting can warm the old grease, making it easier to remove.

The 7-Step Replacement Process

Follow these steps carefully to ensure a proper and leak-free service.

- Safety First: Disconnect the spark plug wire to prevent any chance of an accidental start. Position the snowblower on a level surface.

- Access the Gearbox: You may need to remove the belt cover and belly pan to access the auger housing. The gearbox is located between the two auger halves.

- Drain the Old Grease: Most gearboxes are a “split-case” design held together by several bolts. Place a drain pan underneath, remove the bolts, and carefully separate the two halves. If there’s a drain plug, remove it first.

- Clean Thoroughly: Scrape out all the old grease. Use a degreaser and rags to clean the gears and the inside of the housing completely. Inspect the gears for any chipped teeth or excessive wear.

- Prepare for Reassembly: Clean the mating surfaces of the gearbox halves, removing all traces of the old gasket. Apply a thin, even bead of RTV gasket maker or place the new gasket.

- Fill with New Grease: Add the new “00” grease. A common mistake is overfilling. The gearbox should only be filled about two-thirds to three-quarters full to allow for expansion.

- Reassemble and Check: Bolt the case halves back together, tightening the bolts in a crisscross pattern. Reassemble the rest of the snowblower, reconnect the spark plug, and run the augers for a minute to distribute the new grease. Check for any leaks.

Advanced Gearbox Maintenance: Beyond Just Grease

True long-term reliability involves more than just periodic grease changes. It requires a proactive approach to inspection and understanding the hidden failure points that many owners overlook. This is where you can truly extend the life of your machine.

The “Packed for Life” Myth

Many manufacturers claim their gearboxes are “lubricated for life.” While the grease used at the factory is high-quality, “life” is a subjective term. The intended “life” of the component may be far shorter than the potential lifespan of the entire machine if properly maintained. Believing this myth is a direct path to premature failure.

Seals wear out. The constant heating and cooling cycles can degrade the lubricant over many seasons. A proactive check every couple of years, even on a “sealed” unit, is the best insurance against a mid-storm breakdown.

Inspecting for Wear and Tear

When you have the gearbox open for cleaning, perform a detailed inspection. Look closely at the teeth of the bronze gear, as this is typically the sacrificial component designed to wear out first. Check for any pitting, scoring, or teeth that appear sharpened to a point.

Also, check the input shaft for side-to-side play. Excessive wobble indicates that the bushings or bearings supporting the shaft are worn. Replacing these small, inexpensive parts during a grease change can prevent catastrophic failure down the road.

Frequently Asked Questions (FAQ)

How often should I check my snowblower gearbox grease?

A visual check of the level and condition via the fill plug should be done annually. A complete drain and refill are recommended every 3-5 seasons, or sooner if the machine sees heavy use or if you notice any leaks or unusual noises.

Can I just top off the grease?

While you can add grease if the level is low, it’s not a substitute for a full replacement. Topping off doesn’t remove contaminants like metal shavings or water that may be suspended in the old grease.

What if my gearbox is leaking?

If you notice grease or oil leaking, it means a seal or gasket has failed. This must be addressed immediately. Continuing to run a leaking gearbox will lead to lubrication starvation and certain failure. Replacing the seals is often possible without replacing the entire gearbox.

Final Words

In the end, your snowblower’s auger gearbox is more than just another part—it’s the core of your machine’s strength. A little attention here pays off in a big way. By checking the gearbox oil or grease level before each season and topping it off with the right lubricant, you’re protecting the gears from wear, corrosion, and eventual failure. It’s a simple bit of maintenance that can save you hundreds of dollars and countless headaches. Treat your gearbox right, and your snowblower will keep tearing through winter’s worst for years to come.