Tecumseh Carburetor Leaking Gas From Vent Hole? Here’s the Fix

There are few things more alarming than the smell of gasoline where it shouldn’t be. A puddle of fuel dripping from your small engine is not just a waste of money; it’s a significant fire hazard. When you see gas leaking from the vent hole of a Tecumseh carburetor, it’s a clear signal of an internal problem that demands immediate attention.

This leak is a classic symptom of a fuel delivery system in crisis. Ignoring it can lead to hard starting, poor engine performance, and even catastrophic failure. Fortunately, this is a problem you can diagnose and repair yourself with the right knowledge and a systematic approach.

You'll Learn About

Why Your Carburetor Vent is Gushing Fuel (And Why You Must Act Now)

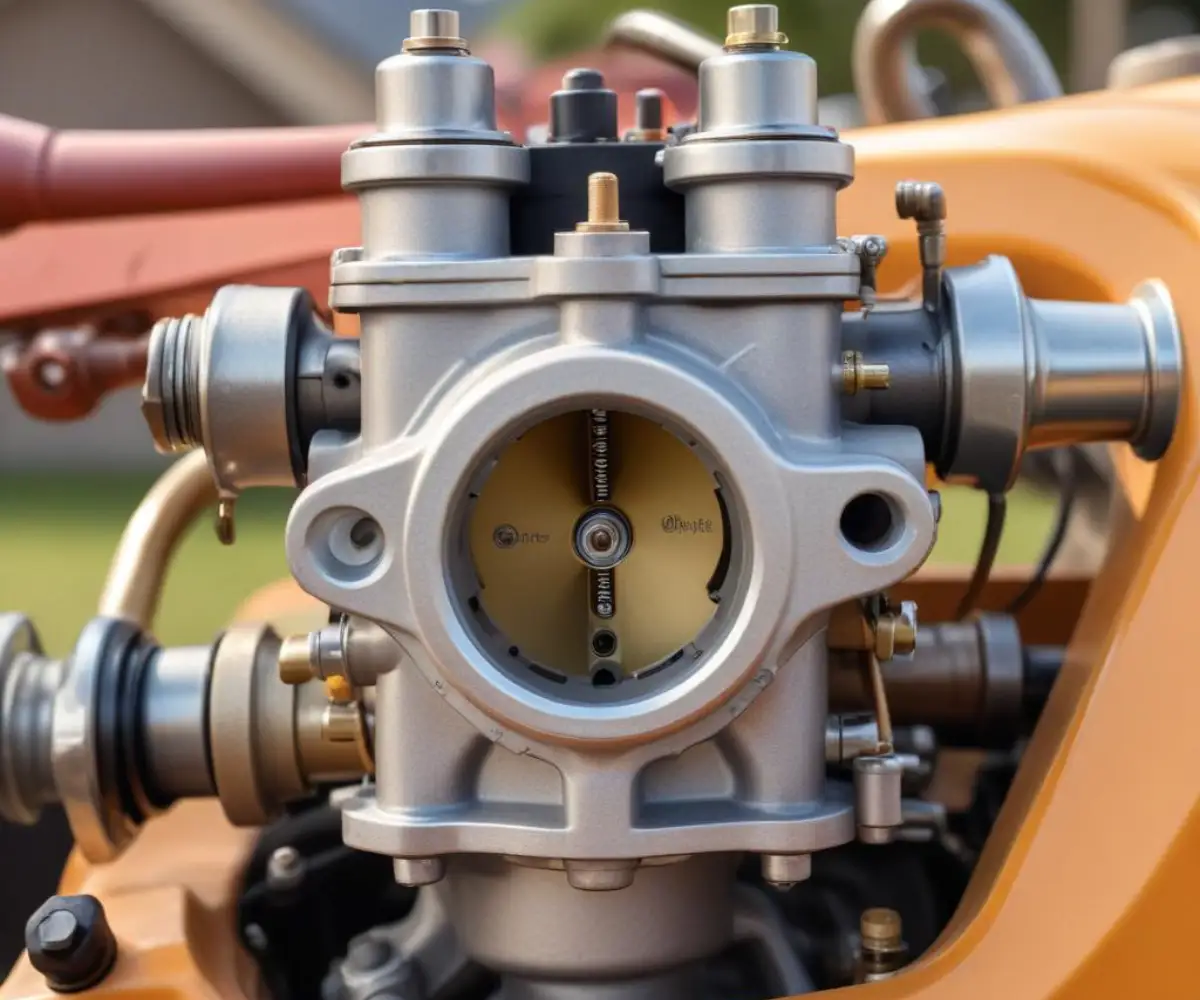

The vent hole on your carburetor serves a critical purpose: it allows atmospheric pressure into the float bowl. This pressure ensures that fuel is pushed smoothly through the carburetor’s jets and into the engine. It is designed for air, not for gasoline to escape.

When fuel leaks from this opening, it means the float bowl is overfilling with gasoline, a condition similar to a constantly running toilet tank. The excess fuel has nowhere else to go, so it escapes through the vent tube. This is a dangerous situation that creates a serious risk of fire and can damage your engine by flooding the crankcase with gasoline.

The Heart of the Problem: A Malfunctioning Float System

The vast majority of vent hole leaks on Tecumseh carburetors trace back to a failure in the float assembly. This system is designed to be a simple but effective fuel shutoff valve. It consists of a float, a needle, and a seat, all working in harmony to maintain the correct fuel level inside the carburetor bowl.

When the fuel level is low, the float drops, pulling the needle away from the seat and allowing gas to enter. As the bowl fills, the float rises, pushing the needle into the seat and stopping the flow. When this delicate balance fails, the bowl overflows, and gas pours from the vent.

The Top 3 Causes of a Leaking Tecumseh Carburetor

Diagnosing the leak starts with understanding the specific ways the float system can fail. While it may seem complex, the issue almost always comes down to one of three culprits. Each requires a slightly different inspection process to identify correctly.

1. A Failed, Saturated, or Sunken Float

The float itself can be the source of the failure. Tecumseh engines have used both hollow brass floats and solid composite floats over the years. Both types can fail in distinct ways that lead to a sunken position, permanently keeping the fuel valve open.

Older brass floats can develop microscopic pinholes or cracks in their solder joints. Over time, gasoline seeps inside, causing the float to lose its buoyancy and sink. Newer composite or plastic floats are immune to this, but they can become saturated with fuel additives or degrade over time, causing them to become heavy and sink.

2. A Worn, Damaged, or Dirty Needle and Seat

The needle and seat form the crucial seal that stops fuel flow. The needle typically has a soft, rubber-like Viton tip that presses against a brass seat. The slightest imperfection in this seal will allow fuel to bypass the valve and overfill the bowl.

The most common cause of failure is debris. A tiny speck of dirt, rust, or degraded fuel line can get lodged between the needle and the seat, preventing it from closing completely. Furthermore, the ethanol present in modern gasoline can be corrosive, causing the needle’s rubber tip to swell, harden, or develop a groove over time, rendering it unable to seal properly.

3. An Improperly Set Float Height

The float height, or level, is a critical adjustment that determines how much fuel enters the bowl before the needle valve closes. If the float is set too high, it will allow too much gas in before shutting off the flow, leading to an overflow. This is often an issue after an incorrect reassembly or if the float’s metal tang has been accidentally bent.

This setting must be precise. Even a small deviation from the manufacturer’s specification can cause persistent leaking. Properly setting the float level is arguably the most overlooked step in a carburetor rebuild, yet it is essential for leak-free operation, a principle of precision that applies whether you’re working on an engine or evaluating equipment like in our Ariens 520 Snowblower Review.

Your Complete Step-by-Step Repair Guide

Fixing the leak requires a methodical disassembly, inspection, and reassembly of the carburetor. Rushing this process or skipping steps will only lead to frustration and continued problems. Follow these steps carefully for a successful repair.

Step 1: Safety and Preparation

Before you begin, safety is paramount. Work in a well-ventilated area away from any open flames or sources of ignition, like a water heater or furnace. Disconnect the spark plug wire to prevent any chance of an accidental engine start.

Have a fire extinguisher nearby as a precaution. It’s also wise to drain the fuel tank into an approved container. Place a rag or drip pan under the carburetor to catch any residual fuel as you work.

Step 2: Carburetor Removal and Disassembly

First, turn off the fuel shutoff valve, if equipped. Use pliers to slide the clamp off the fuel line and carefully pull the line from the carburetor inlet. Next, remove the air filter and its housing to gain access to the two bolts or nuts holding the carburetor to the engine.

Once the carburetor is free, place it on a clean workbench. The float bowl is held on by a single bolt at the bottom. Carefully remove this bolt and gently lower the bowl, being mindful of the rubber O-ring or gasket that seals it.

Step 3: In-Depth Inspection of Internal Components

With the bowl removed, you can see the float assembly. It’s held in place by a small pin; gently push this pin out with a small punch or nail to release the float and the attached needle valve. Now, inspect each component meticulously.

Check the float itself. If it’s a brass float, shake it next to your ear to listen for any sloshing liquid inside. Examine the needle’s Viton tip under a magnifying glass for any grooves, pitting, or signs of hardening. Finally, look inside the brass seat for any visible debris or scoring.

The Undetectable Problem: Invisible Varnish on the Seat

Sometimes, a needle and seat will continue to leak even when they appear perfectly clean and undamaged. This frustrating situation is often caused by a microscopic layer of fuel varnish on the brass seat. This invisible film, left behind by evaporated old fuel, is just thick enough to prevent the soft needle tip from creating a perfect seal.

You cannot see this varnish, but you can remove it. A simple yet highly effective trick is to use a fresh cotton swab dipped in a quality metal polish. Gently twist the swab inside the brass seat for a few seconds. This mild abrasive action will remove any imperceptible residue and restore the smooth sealing surface without damaging the brass.

The Definitive Solution: Rebuild or Replace?

While cleaning the components might solve a leak caused by simple debris, it’s often a temporary fix. Given the low cost of a carburetor rebuild kit, a full rebuild is always the recommended course of action. These kits include a new needle, seat, bowl gasket, and other essential O-rings that wear out over time.

A rebuild ensures all sealing surfaces are fresh and addresses the potential for worn-out rubber parts. This is the most reliable way to guarantee a long-term solution. When parts are this critical, precision is key, just as it is when determining the correct John Deere 826 Snowblower oil capacity to prevent engine damage.

Setting the Float Level: The Most Critical Adjustment

After installing the new needle and seat from your kit, you must set the float level correctly. This step is non-negotiable for preventing leaks. With the carburetor body held upside down, the float should rest gently on the needle without compressing its spring-loaded plunger.

The correct setting is when the float sits perfectly parallel to the carburetor body surface. A common and effective tool for measuring this is the shank of a 11/64″ drill bit placed across the carburetor body. The float should just touch the drill bit. If it needs adjustment, gently bend the small metal tang that makes contact with the needle, not the main arms of the float itself.

| Failure Point | Primary Symptom | Recommended Solution |

|---|---|---|

| Debris in Needle & Seat | Sudden, persistent leak from vent hole. | Disassemble and clean with carburetor spray. Install an inline fuel filter. |

| Worn Needle Tip | Slow, intermittent drip that may worsen over time. | Replace with a full carburetor rebuild kit. |

| Sunken Brass Float | Heavy, constant fuel leak immediately after fuel is turned on. | Replace the float. It is best to do this as part of a full rebuild. |

| Incorrect Float Level | Leaking immediately after a rebuild or cleaning attempt. | Re-open carburetor and adjust float level to be parallel with the carb body. |

| Fuel Varnish on Seat | Leak persists even with a new needle and a visually clean seat. | Polish the brass seat with a cotton swab and metal polish. |

Advanced Prevention and Final Checks

Once you’ve rebuilt the carburetor and reinstalled it, there are steps you can take to prevent the problem from recurring. The single most important preventative measure is to use fresh, ethanol-free fuel whenever possible, or at the very least, a high-quality fuel stabilizer.

Installing a cheap inline fuel filter between the tank and the carburetor is another excellent preventative measure. This will catch any dirt, rust, or debris before it has a chance to foul the new needle and seat. This is especially important for older equipment, like a vintage Homco snowblower, where the fuel tank may have accumulated sediment over the years.

What If It Still Leaks?

If you have performed a full rebuild and correctly set the float height, but the leak persists, the issue may lie with the carburetor body itself. Look for any hairline cracks in the body, particularly around the fuel inlet or the brass seat housing. While rare, this can happen and would require a full carburetor replacement.

Additionally, on the rare Tecumseh engines equipped with a fuel pump, verify that the pump is not producing excessive pressure. A faulty pump can overwhelm even a brand-new needle and seat, forcing fuel past the seal and out the vent.

Conclusion: Taking Control of Your Equipment

A Tecumseh carburetor leaking gas from the vent hole is a serious issue, but it is not an insurmountable one. By understanding that the problem lies within the float system, you can move past the initial alarm and begin a logical diagnostic process. The key is to be meticulous in your inspection and to replace the critical wear components with a rebuild kit.

By carefully cleaning the components, polishing the seat, installing new parts, and accurately setting the float level, you can permanently solve the leak. You will not only save money on repairs but also gain the confidence that comes from mastering your own machine.