Polystyrene Compatible Caulk: Stop Melting Your Insulation Now!

There are few home improvement moments more frustrating than applying a bead of caulk to expensive polystyrene foam board, only to watch in horror as it dissolves the material before your eyes. This common disaster turns a simple sealing job into a costly repair, leaving you with a pitted, melted mess. The core of the problem lies in a fundamental chemical incompatibility that many people discover far too late.

Polystyrene, whether it’s the extruded (XPS) or expanded (EPS) type, is a sensitive plastic. The wrong sealant can instantly compromise its structure, ruining its insulative properties and aesthetic finish. Understanding this reaction is the first step toward preventing it and completing your project with professional results.

You'll Learn About

Why Regular Caulk Destroys Polystyrene: The Science Explained

The destructive reaction between common caulks and polystyrene is a matter of chemistry. Polystyrene foam is a hydrocarbon polymer, meaning its molecular structure is vulnerable to certain types of chemicals. Many standard caulks and construction adhesives are packed with aggressive solvents designed to keep the product pliable in the tube and promote adhesion.

These solvents, which often include chemicals like acetone, xylene, toluene, and other petroleum distillates, are the primary culprits. When they come into contact with polystyrene, they act like a chemical wrecking ball, breaking down the polymer chains that give the foam its solid structure. This process is not a “melting” from heat, but a chemical dissolution, causing the foam to soften, shrink, and collapse.

The Solvents to Watch Out For

The most significant mistake is grabbing a generic tube of all-purpose caulk without scrutinizing the label. Products like standard construction adhesives, many types of 100% silicone that release acetic acid during curing (the source of a strong vinegar smell), and certain acrylic latex formulas contain these harsh solvents. The damage is irreversible and requires cutting out and replacing the affected foam, wasting both time and money.

Properly sealing your home is not just about insulation; it’s about a complete safety and efficiency envelope. Ensuring utility penetrations are correctly sealed is critical. Issues like a rusted gas line can be exacerbated by moisture intrusion from improper sealing, highlighting the need for the right materials in the right places.

The Solution: What Makes a Caulk “Polystyrene-Safe”?

A caulk is deemed “polystyrene-safe” when it is formulated without the aggressive solvents that dissolve the foam. Manufacturers achieve this in several ways, leading to a few key types of compatible products you can confidently use for your projects. These sealants are designed to bond effectively without causing any chemical damage.

The safest options are typically water-based acrylic latex caulks or sealants specifically labeled as “for foam board” or “polystyrene safe.” Other reliable choices include neutral-cure silicones, which do not release acetic acid, and specialized polyurethane foam adhesives. Always check the product’s technical data sheet (TDS) on the manufacturer’s website for explicit confirmation of compatibility.

Key Characteristics of Foam-Safe Caulk:

- Solvent-Free or Water-Based: These products use water as their base instead of harsh chemicals, making them gentle on polystyrene. They also offer the benefit of easy soap-and-water cleanup.

- Low VOC (Volatile Organic Compounds): Low-VOC formulas are less odorous and safer for indoor air quality, and they tend to omit the aggressive solvents that harm foam.

- Clearly Labeled for Foam Applications: Manufacturers like Loctite (PL 300) and Liquid Nails make products specifically for foamboard. These are your most reliable choices.

How to Choose the Right Polystyrene Compatible Caulk for Your Project

Selecting the ideal caulk depends on the specific demands of your project. Are you sealing gaps in interior insulation, bonding panels to a concrete wall, or sealing joints on an exterior application? Each scenario requires different properties like flexibility, paintability, and weather resistance. A crucial part of home safety involves paying attention to warning signs. For example, if you ever notice a light switch glowing orange when sealing around electrical boxes, stop work immediately and consult an electrician.

The following table breaks down the most common types of polystyrene-safe caulks and adhesives to help guide your decision.

Caulk & Adhesive Comparison for Polystyrene Applications

| Caulk/Adhesive Type | Best For | Paintable? | Flexibility | Key Feature |

|---|---|---|---|---|

| Water-Based Foamboard Adhesive (e.g., Loctite PL 300) | Bonding foam panels to substrates (wood, concrete, drywall) and filling larger gaps. | Yes (after full cure) | Low to Medium | High grab strength, reduces need for fasteners. |

| Siliconized Acrylic Latex Caulk | Sealing interior joints and gaps around windows, doors, and trim. | Yes | Medium | Easy water cleanup, good paintability. |

| Neutral-Cure Silicone Sealant | Exterior applications, windows, and areas needing high flexibility and waterproofing. | Some formulas are paintable, but check the label. | High | Excellent weather/UV resistance, durable flexibility. |

| Low-Expansion Polyurethane Foam (Canned Foam) | Filling large, irregular gaps around pipes, vents, and wall penetrations. | Yes (after trimming and curing) | Low | Expands to fill voids completely, excellent insulator. |

Step-by-Step Guide: Applying Caulk to Polystyrene Perfectly

Proper application is just as important as choosing the right product. Following these steps will ensure a clean, effective, and long-lasting seal that protects your polystyrene project.

First, ensure all surfaces are clean, dry, and free from dust or grease. Good preparation is the foundation of good adhesion. If working in a dusty environment, wipe the foam surface with a damp cloth and allow it to dry completely.

The Crucial Patch Test

Always test the caulk on a scrap piece of the same polystyrene material before applying it to your main project. This non-negotiable step is your final safeguard against a chemical reaction. Apply a small amount and wait a few minutes to see if any pitting, softening, or dissolving occurs.

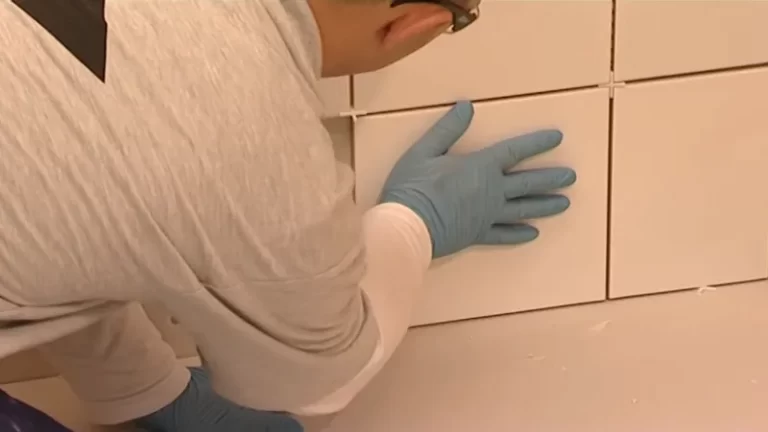

Application and Tooling

Cut the nozzle of the caulk tube at a 45-degree angle to create a bead size appropriate for your gap. Puncture the inner seal with a nail or the tool on the caulk gun. Apply a steady, consistent bead by pushing the caulk gun smoothly along the joint. For a professional finish, immediately smooth the bead (a process called “tooling”) with a caulk tool or a wet finger to press the sealant into the joint and remove excess.

Common Mistakes to Avoid When Sealing Polystyrene Foam

Even with the right materials, simple mistakes can lead to a subpar finish or a failed seal. Avoiding these common pitfalls is key to success.

- Ignoring the Product Label: This is the most common error. The label is your primary source of information. Look for keywords like “for foamboard,” “polystyrene safe,” or “solvent-free.”

- Applying in Extreme Temperatures: Most caulks have an ideal application temperature range, typically between 40°F and 100°F (4°C and 38°C). Applying caulk in conditions that are too hot or too cold can affect how it cures and adheres.

- Over-filling Gaps: Using too much caulk creates a messy look and wastes material. For very large gaps (over 1/2 inch), it is better to use a backer rod or low-expansion spray foam first.

Beyond Caulk: Other Methods for Sealing and Joining Polystyrene

While caulk is excellent for sealing gaps, other products are better suited for different tasks, such as joining large panels or sealing around complex shapes.

Foam Board Adhesives: Products like Loctite PL 300 or Liquid Nails for Foamboard are designed specifically for bonding polystyrene panels to each other or to other construction materials like wood, metal, or concrete. Their high-grab formula often minimizes the need for mechanical fasteners while the adhesive cures.

Specialty Tapes: For creating an air and moisture barrier at the seams of insulation boards, polypropylene sheathing tapes (like Tyvek Tape or Tuck Tape) are an excellent choice. These tapes have an aggressive acrylic adhesive that bonds strongly to the foam’s surface.

Frequently Asked Questions (FAQ)

Can I use any silicone caulk on Styrofoam?

No. You must use a neutral-cure silicone. Standard acid-cure silicone, which has a strong vinegar smell, will damage polystyrene. Always verify that the silicone is safe for plastics and foam.

Will all acrylic latex caulks work on polystyrene?

Not necessarily. While many water-based acrylic latex caulks are safe, some cheaper “painter’s caulk” varieties may contain solvents to improve adhesion to other surfaces. It is vital to choose one that is explicitly labeled as solvent-free or safe for foam.

What’s the best way to fill a large, awkward gap around a pipe through a foam board?

For large, irregular gaps, low-expansion canned spray foam is the ideal solution. It expands to perfectly fill the void, providing both an air seal and insulation. After it cures, you can trim the excess foam flush with the board.

What should I do if I accidentally used the wrong caulk?

If you notice the foam dissolving, stop immediately. You will need to carefully cut away the damaged section of the polystyrene. Once the area is clean and the caulk is removed, you can patch it with a new piece of foam, securing it with a compatible adhesive.

Achieving a Professional, Long-Lasting Seal

Working with polystyrene doesn’t have to be a gamble. The key to a successful project is understanding the chemical sensitivity of the material and diligently selecting a compatible, solvent-free caulk or adhesive. By reading labels carefully, performing a patch test, and using proper application techniques, you can achieve a durable, professional seal that preserves the integrity of your insulation or craft project.

Remember that a well-sealed home is a safe home. This includes being aware of all safety systems, from insulation to alarms. If you ever find your fire alarm made one loud beep, it’s a signal to investigate the unit’s status, ensuring everything is functioning correctly to protect your home.