Maintain 404a Freezer Pressures [Essential Read]

R-404A is a widely used refrigerant in commercial freezers. It is known for its effectiveness in maintaining low temperatures and its compatibility with a variety of refrigeration systems. However, like all refrigeration systems, it is crucial to monitor and maintain the pressures within the system to ensure optimal performance and prevent potential issues.

In this blog post, we will discuss the normal operating pressures for R-404A refrigerant in a freezer, the use of PT charts to determine expected pressures, high pressure concerns, and the importance of regular maintenance and troubleshooting.

You'll Learn About

404a Freezer Pressures

R-404A is a refrigerant commonly used in commercial freezers. The normal operating pressure for R-404A in a freezer at a temperature of 70 degrees Fahrenheit and a suction temperature of 30 degrees Fahrenheit would be around 9.6 psi. The low pressure should be 18-20 psi while the high pressure should be around 200 psi.

However, this can vary depending on the specific conditions of the freezer and the specific equipment being used. The normal head pressure for R-404A in a freezer should be between 210-260 psi. If the head pressure is outside of this range, it could indicate an issue with the system and should be checked by a qualified technician.

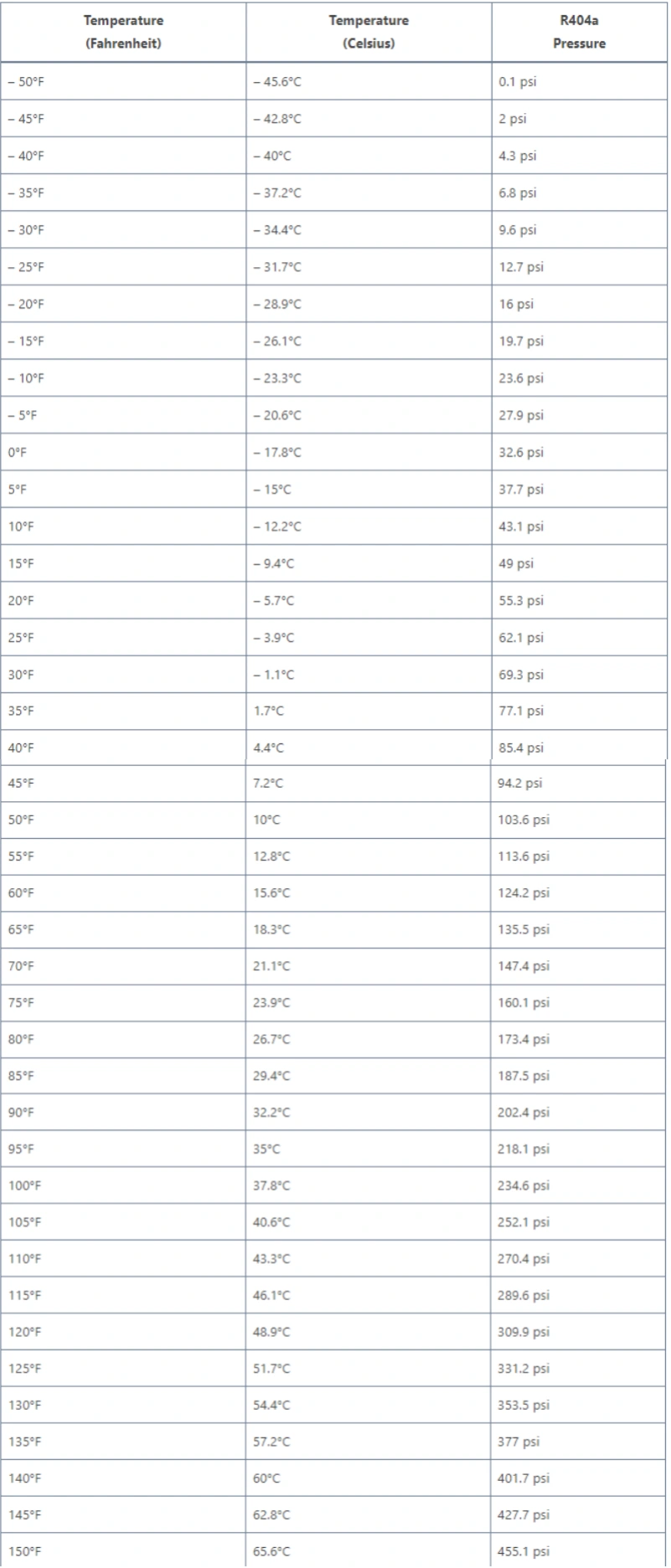

The PT chart for R-404A can be used to determine the expected pressures at different temperatures, and to identify any potential problems with the system.

Normal Operating Pressures

Factors that affect normal operating pressures include the ambient temperature, the temperature of the refrigerant, and the specific equipment being used. These factors can all affect the pressures within the system and should be taken into account when determining the normal operating pressures for a specific freezer.

Temperature and Pressure

Temperature and pressure correlation are closely related in a refrigeration system. As the temperature of the refrigerant decreases, the pressure within the system will also decrease. Conversely, as the temperature of the refrigerant increases, the pressure within the system will also increase.

This relationship is important to understand when monitoring pressures in a freezer system.

Normal Head Pressure

The normal head pressure range for R-404A in a freezer is between 0.9psig – 460psig. It’s important to regularly check the head pressure to ensure that it falls within this range. If the head pressure is outside of this range, it could indicate an issue with the system and should be checked by a qualified technician.

Using a Pt Chart

A PT chart, also known as a pressure-temperature chart, is a graphical representation of the relationship between pressure and temperature for a specific refrigerant. It is used to determine the expected pressures at different temperatures and to identify any potential problems with the system.

To use a PT chart to determine expected pressures, the operator must first identify the current temperatures of the refrigerant and the ambient temperature. These temperatures can then be located on the chart and the corresponding pressure can be read. This will give an idea of the expected pressure at the given temperatures.

By using a PT chart, it is possible to identify potential problems with the system. For example, if the actual pressure is significantly higher or lower than the expected pressure, it could indicate a problem with the system such as a leak or malfunctioning equipment. Additionally, if the pressure and temperature points do not fall within the expected range on the chart, it can also indicate a problem and should be addressed by a qualified technician.

High Pressure Concerns

High pressure in a freezer system can be caused by a number of factors, including a malfunctioning compressor, a restriction in the refrigerant flow, or a lack of refrigerant in the system. Additionally, high ambient temperatures can also cause an increase in pressure within the system.

Signs of high pressure in a freezer system include a high head pressure reading, a hot compressor, and a reduced cooling capacity. Additionally, the pressure relief valve may activate if the pressure becomes too high, which can also indicate high pressure in the system.

High pressure in a freezer system can have serious consequences if left unaddressed. It can cause damage to the compressor and other equipment, reduce the efficiency of the system, and even lead to equipment failure.

Additionally, high pressure can also increase the risk of refrigerant leaks, which can be dangerous and costly to repair. Therefore, it’s important to address any high pressure issues as soon as they are identified to prevent further damage and ensure the safe and efficient operation of the freezer system.

Maintenance and Troubleshooting

Maintenance and Troubleshooting: A. Regular maintenance is crucial to ensure the safe and efficient operation of a freezer system. This includes checking and adjusting pressures, cleaning and maintaining equipment, and ensuring that the refrigerant levels are at the proper levels.

By performing regular maintenance, potential problems can be identified and addressed before they become major issues.

Common issues that can affect freezer pressures include leaks, restriction in the refrigerant flow, and malfunctioning equipment. Additionally, high ambient temperatures and a lack of maintenance can also contribute to pressure problems.

To troubleshoot pressure problems, the first step is to check the pressures and temperatures using a PT chart to determine if they fall within the expected range. If the pressures are not within the expected range, the next step is to check for leaks, restrictions in the refrigerant flow, and malfunctioning equipment.

If the problem cannot be identified and resolved, it is important to call a qualified technician to inspect and repair the system. Additionally, it’s important to keep in mind that refrigeration systems should be handled only by professionals with adequate training and experience.

How to Provide Good 404a Freezer Pressures?

- Always wear protective gear, including gloves and safety glasses, when handling R-404A refrigerant.

- Be sure to properly evacuate and charge the system with the correct amount of refrigerant. Overcharging or undercharging can cause high or low pressure issues.

- Keep the condenser coils clean and free of debris to ensure proper heat transfer and prevent high head pressures.

- Check for any leaks in the system, as even small leaks can cause pressure imbalances. Use leak detection methods such as a halide torch or electronic leak detector to locate any leaks.

- Have a set of gauges and thermometers on hand to accurately measure and monitor pressures and temperatures in the system.

- Regularly check the refrigerant oil level and quality. Low oil levels or contaminated oil can cause compressor failure and pressure imbalances.

- Check the compressor for any mechanical issues such as worn or damaged bearings, which can cause the compressor to work harder and increase head pressure.

- Monitor the suction pressure, if the suction pressure is too low, it can cause low head pressure, and abnormal head or suction pressure, and compressor issues.

- Check the proper function of the thermostatic expansion valve, if the valve is not functioning properly, it can cause low head pressure or high head pressure.

- Regularly check the refrigeration system’s performance, by analyzing the cooling capacity, energy consumption and compressor’s power consumption, this will help you to detect any issues in the early stage before it leads to major problem.

Frequently Asked Questions

What Are the Typical Applications for R-404a Refrigerant?

R-404A refrigerant is commonly used in medium and low temperature commercial and industrial refrigeration applications, such as refrigerated warehouses, supermarkets, and ice rinks. It is also used in some transport refrigeration systems and in some residential and light commercial air conditioning systems.

How Does R-404a Compare to Other Refrigerants in Terms of Efficiency and Environmental Impact?

R-404A has a lower Global Warming Potential (GWP) than R-22, a refrigerant that is being phased out due to its high GWP. However, R-404A still has a relatively high GWP compared to newer refrigerants such as R-407F, R-134a, and R-744. In terms of efficiency, R-404A can be less efficient than newer refrigerants, but it is still widely used due to its availability, performance, and compatibility with existing equipment.

How Do I Know if My Freezer System is Low on R-404a Refrigerant?

One sign that a freezer system may be low on R-404A refrigerant is a decrease in the system’s cooling capacity. Additionally, if the head pressure is lower than normal, it could be an indication of a low refrigerant charge. Another sign of a low refrigerant charge is if the compressor is running excessively or if the suction pressure is too low.

Can I Use R-404a Refrigerant in My Residential Air Conditioning System?

While R-404A can be used in some residential air conditioning systems, it is not typically recommended for residential use due to its high GWP and the availability of more efficient and environmentally friendly refrigerants. It’s always important to consult your equipment manufacturer’s recommendations and consult with a qualified HVAC technician before making any changes to your system.

What Should I Do if I Suspect a Leak in My R-404a Freezer System?

If you suspect a leak in your R-404A freezer system, it is important to address the issue as soon as possible to prevent further refrigerant loss and potential damage to the system. The first step is to locate the leak, which can typically be done with a refrigerant leak detector or by visually inspecting the system.

Once the leak has been located, it should be repaired by a qualified technician. Additionally, it’s important to monitor the refrigerant levels and pressures after repair to ensure that the system is functioning properly.

Remember that refrigeration systems should be handled only by professionals with adequate training and experience.

Conclusion

Monitoring and maintaining the pressures within a freezer system that uses R-404A refrigerant is crucial for ensuring the safe and efficient operation of the system. By understanding the factors that affect normal operating pressures, using a PT chart to determine expected pressures, and being aware of the signs of high pressure, potential problems can be identified and addressed before they become major issues.

Regular maintenance is also important to ensure the system is functioning properly and to prevent pressure problems from occurring. It’s also important to consult professional refrigeration technicians when troubleshooting or performing maintenance to ensure the safe and efficient operation of the system.

Additionally, there are several resources available for more information on R-404A refrigerant and freezer pressures, including industry websites and technical manuals.